Description

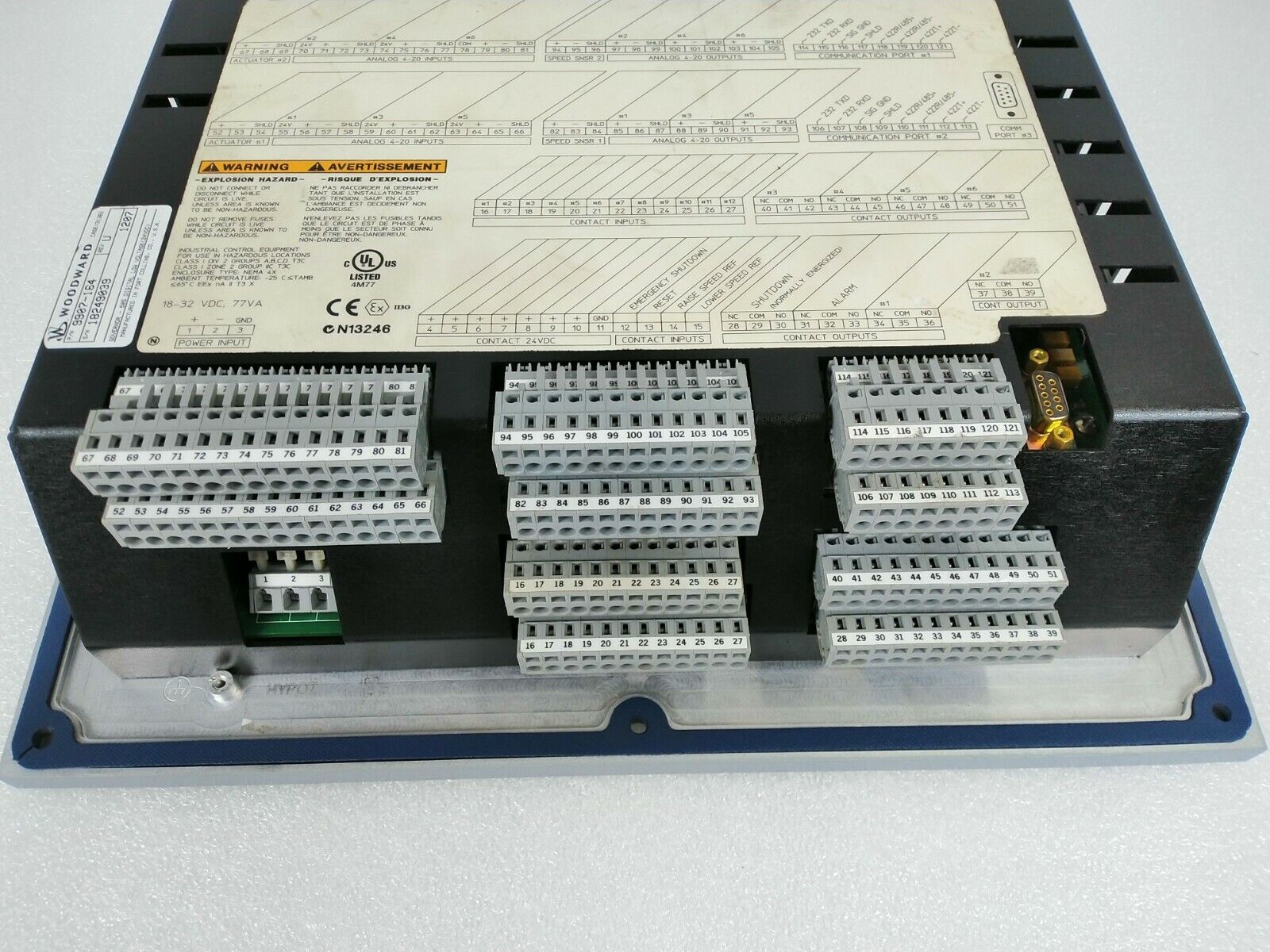

WOODWARD 9907-167 is a steam turbine digital governor used to control the speed of the steam turbine to achieve the forward and stop of the ship. It is one of the commonly used control equipment in steam and power generation, power plant and other industrial fields.

WOODWARD 9907-167 Steam turbine digital governor by collecting the speed signal of the steam turbine, according to the preset control logic and parameters, automatically adjust the gas intake, exhaust and other parameters of the steam turbine, in order to achieve the stable operation of the steam turbine and the accurate control of the output power. It has the characteristics of high precision, high stability and fast response, and can adapt to different types of steam turbines and operating environments.

When WOODWARD 9907-167 turbine digital governor is used, the configuration and control program need to be written according to the specific industrial application scenario. It is usually necessary to connect the sensor and the actuator, set the communication interface and parameters, write the control program, and download the program to the governor. During operation, the governor will automatically adjust and stabilize according to the actual control requirements to ensure the normal operation of the turbine and the accurate control of the output power.

In short, WOODWARD 9907-167 steam turbine digital governor is an important industrial control equipment, widely used in steam and power generation, power plants and other industrial fields. It can improve the operation efficiency and stability of the steam turbine, and reduce the labor intensity and error rate of the operator, which provides an important guarantee for the stable operation of the industrial automation control system.

WOODWARD 9907-167 The use of the Woodward Turbine digital governor consists of the following steps:

Installation and connection: Install the governor to the control cabinet or operating platform near the steam turbine, and connect the sensor and actuator according to the instructions to ensure correct signal transmission and action execution.

Power supply and communication: Provide the required power supply for the governor, and use the appropriate communication interface to connect the governor to the upper computer or monitoring system. Ensure correct configuration and parameter Settings of communication interfaces.

Parameter setting: According to the turbine model, operation requirements and control system requirements, set the control parameters of the governor, such as target speed, start/stop speed, acceleration/deceleration, etc.

Control program writing: The use of supported programming languages (such as C++, C#, etc.) to write control programs, according to the actual control logic and algorithm to achieve the control and operation of the governor. Ensure the correctness and stability of the control program.

Program download and debugging: the written control program is downloaded to the governor, and debugging and testing are carried out to ensure that the governor can operate normally in accordance with the preset control logic and parameters, and can correctly respond to the state changes and operational requirements of the turbine.

Operation and maintenance: Start the steam turbine and control system and run the governor. During operation, it is necessary to pay close attention to the running state and parameter changes of the governor, and adjust and control the speed and output power of the turbine in time. At the same time, regular maintenance and maintenance is also an important measure to ensure the normal operation and service life of the governor.

It should be noted that when using the WOODWARD 9907-167 digital turbine governor, the relevant safety specifications and operating guidelines should be followed to ensure the stability and safety of the system. At the same time, depending on the specific industrial application scenarios and actual needs, additional configuration and control optimization may be required.

【 Main products 】 If you need to send to help you compare the price oh!

Main brands include ABB, Bailey, GE, FOXBORO, Invensys TRNEX,

Bentley BENTLY, A-B Rockwell, EMERSON Emerson, B&R,

MOTOROLA, FUANC, REXROTH, KUKA, HONEYWELL,

NI, DEIF, Yokoho, WOODWARD, Ryan, SCHNEIDER,

Yaskawa, MOOG, EPRO, PROSOFT and other major products

Main activities:

①ABB AC800M series module, industrial robot parts DSQCserIes,BaIley INFI 90,800xA,

Advant OCS wIth Master Software,wIth MOD 300software Advant OCS,Freelance–

Distributed Control System for Process Industry,Symphony Melody,Satt OCS,Symphony DCI System SIx,

Harmony/INFI 90, security system

②SchneIder(Schneider Electric)140 series product CPU module

③General electrIc(General Electric) series products IC693 IC695 IC697 IC698

Relay protection SR469 starts with SR369 starts with SR489 starts with SR750

IS200 / IS215 / IS220 / IS420 / DS200 / DS215 / VMIVME beginning 7750, 7807

(4) TIconex (invensys) series products 3721350, 3435, 1 B, 3625300, 9

⑤Bently(Bentley) 3500 series big card small card 1900 series power module

3500/15 3500/20 3500/22M 3500/42M 3500/25 3500/32 3500/53

⑥Allen-Bradley(US AB) series products 1394 beginning 2711 beginning 1756,1747 and so on

⑦EMERSON/WestInghouse series products OVATION system, WDPF system, MAX0 system spare parts.

DELTAV delta’s VE3008 CE3008 / SE3008 VE3007 / VE3006 SE4006P2

⑧Foxboro(Foxboro) : I/A SerIes system, FBM(field input/output module) sequence control, ladder logic control,

Accident recall processing, digital-to-analog conversion, input/output signal processing, data communication and processing, etc. FCP270/FCP280/FBM201… FBM242

⑨Woodword 9907-9907-5466-316 5501-467 5501- Beginning 8444- Beginning

⑩Bosch Rexroth(Bosch Rexroth) : Indramat, I/O module,PLC controller, drive module, etc.

Motorola: MVME 162, MVME 167, MVME5500, MVME6100 and other series.

Reviews

There are no reviews yet.