Description

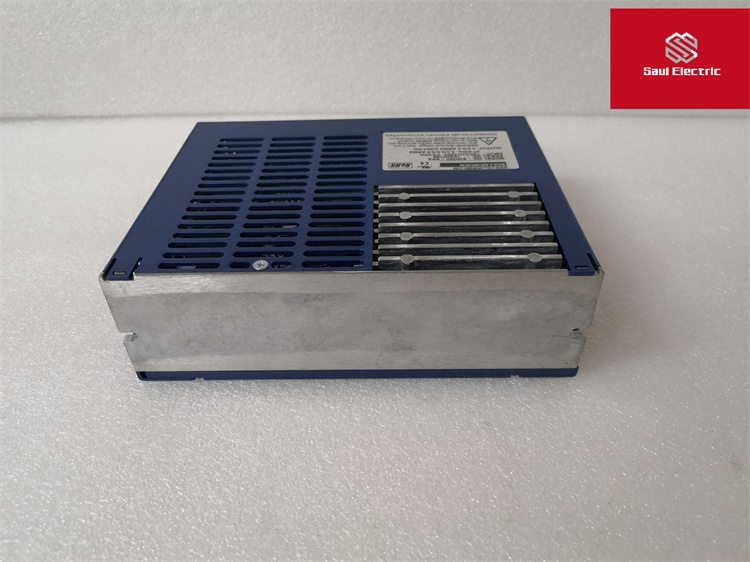

KOLLMORGEN S20360-SRS DANAHER S200 servo drive

Many products are not currently on the shelves please contact us for more products

If the product model is different from the displayed picture, the model shall prevail. Contact us for specific product pictures, and we will arrange to take photos at the warehouse for confirmation

We have 16 shared warehouses worldwide, so sometimes it takes a few hours to accurately return to you, please understand. Of course, we will reply to your concerns as soon as possible and wait patiently

KOLLMORGEN S20360-SRS DANAHER Servo driver Kollmorgen S200 servo driver is the first fully digital industrial driver with speed loop bandwidth of 800 Hz. These compact drives provide simplified tuning and unmatched system throughput, as well as high-resolution feedback

characteristic

Suitable for 120/240 VAC and 20-90 VDC operation, rated for continuous current from 1.5 Amps RMS to 48 Amps RMS peak

24-bit high resolution feedback

3-5 kHz High performance current loop bandwidth

Intelligent feedback devices with electronic motor nameplates eliminate the need for drive parameter setting and servo loop adjustment, allowing plug and play debugging in most applications

Standard features include torque and speed control base, electronic gear, up to 18-bit analog reference input and encoder equivalent output

Options available to support indexing or SynqNet™ -based programmable motion control

Comply with UL 508C, CE, EN50178, EN61800-C and Semi F47 standards

Separate “Keep Alive” power inputs allow quick recovery from emergency stop conditions

benefit

The wide power range allows a single drive family to be deployed throughout the machine

The compact footprint allows for smaller cabinets or installation close to the point of use

Optical isolation input/output, forward locking connectors, and comprehensive fault protection extend machine life and prevent accidental damage

A high-performance system designed to increase machine throughput

The easy-to-use graphical user interface reduces engineering and support time

Reduce total cost

PRDRHP720SNZ-65

RMB-10V2-SYNQNET

RSER200-4

S20330-SRS

S20330-VTS

S20360-SRS

S21260-SRS

S31061-SE-SB

S60300-PB

S70602- Nana Na Na

S70602-NANANA-NA-024

S72402- Nana Na Na

S72402-NANANA-NA-030

S72402-NANANA-NA-225

Servo Star 610

Kollmorgen’s S200 brushless servo drive applies servo technology to the full power range family with DC input and AC input family members. Especially for lower power applications the S200 series offers a comparison without having to compromise on reliability or package size. Coupling the S200 driver to Kollmorgen’s AKM servo motor provides servo control solutions designed to excel in applications such as semiconductor manufacturing, electronic assembly, packaging, medical and woodworking equipment and more.

Kollmorgen’s S200 servo driver is a fully digital industrial driver with speed loops up to 800Hz bandwidth, providing system throughput and simplified tuning. High resolution (24-bit) feedback and 3-5 KHZ current loop bandwidth provide smooth motion and fast start and stop actions to optimize machine performance. Smart feedback and high bandwidth provide fast and accurate “plug and play” debugging by eliminating the need for servo-loop tuning in most applications. The basic S200 servo drive comes standard with torque or speed control, as well as the factory option CANopen communication that supports SynqNet motion networking or adds a preconfigurable index. The Factory TAB also adds interface feedback devices for additional motors, such as Comcoder, 1 Vp-p Sin Cos, EnDat 2.1 and EnDat 2.2 Run 2.1 compatibility mode. The tabbed EnDat interface can accommodate single – and multi-turn rotation or incremental and linear encoders. The drive uses AC (120/240 VAC) or DC (20-90 VDC) power and is rated for 1.5ARMS continuous to 48 ARMS peak. Its compact footprint ranges from 1.1 inches (28.7 mm) wide and 6.0 inches (152.4 mm) high to 3.8 inches (94.6 mm) wide and 6.39 inches (213 mm) high and depth from 3.9 inches (100.8 mm) to 7.57 inches (192.4 mm), allowing it to fit the space tightly. They are UL 508C certified, CE certified and comply with EN50178 and EN61800-3.

The original S200 series included lead in the welds. The subsequent units were manufactured in full compliance with the EU RoHS Environmental Directive in November 2007. RoHS instruction units also have 3.0A or later control logic.

Reviews

There are no reviews yet.