Description

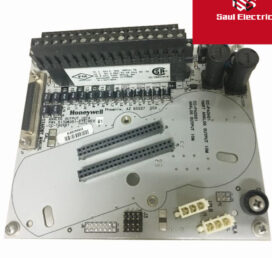

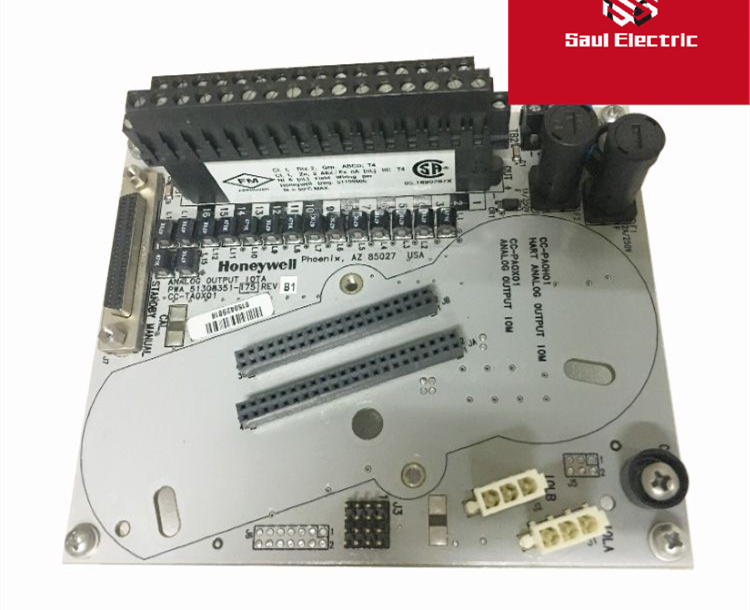

The Honeywell CC-PCNT02 output communication module is a powerful industrial automation control module:

1、 Product Overview

Brand: Honeywell

Model: CC-PCNT02

Type: Output Communication Module

2、 Main features

High reliability: The CC-PCNT02 module has high reliability and stability, and can operate normally under harsh environmental conditions, ensuring the stability and safety of industrial automation control systems.

Multiple input and output channels: This module has multiple input and output channels, supports multiple different signal types and communication protocols, and can meet various control requirements.

Remote monitoring and management: Supports multiple communication protocols such as Ethernet and Profinet, making it convenient for users to remotely monitor and manage equipment, improving the efficiency and convenience of industrial automation control systems.

Seamless integration: The CC-PCNT02 module can be seamlessly integrated with other automation instrumentation products, improving the reliability and stability of the entire control system.

Internal diagnostic function: Supports a wide range of internal diagnostics to ensure data integrity, and has an open circuit detection function, further enhancing the reliability and stability of the module.

3、 Technical specifications

Working voltage: usually 220V (specific voltage range may vary depending on product version)

Power: 2700W (specific power may vary depending on product version and actual application scenario)

Size: 26 * 33 * 37 (unit may be in mm, specific size may vary depending on product version)

Weight: 2.3kg (specific weight may vary depending on product version and manufacturing tolerances)

Supporting systems: Industrial automation control systems such as PLC/DCS systems

4、 Application scenarios

The CC-PCNT02 output communication module is widely used in various industrial automation control systems, such as DCS (distributed control system), PLC (programmable logic controller), etc. It can be used to connect various industrial automation equipment, achieve data transmission and control, and improve production efficiency and quality.

5、 Usage and maintenance

Installation: The correct installation should be carried out according to the instructions in the product manual to ensure that the module is properly connected to other parts of the system.

Configuration: Use configuration tools to make necessary settings for modules to meet specific application requirements.

Maintenance: Regularly check the working status of the module to ensure that it is in good operating condition. If any abnormal situation is found, timely measures should be taken to handle it.

6、 Precautions

During use, safety regulations and operating procedures in the product manual should be followed to ensure the safety of personnel and equipment.

Avoid using modules in harsh environmental conditions to avoid affecting their performance and lifespan.

Reviews

There are no reviews yet.