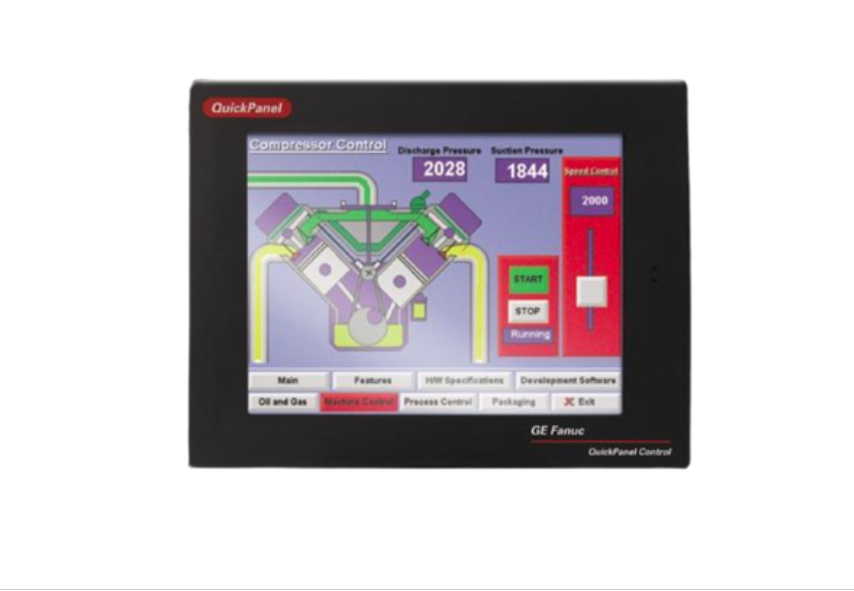

Description

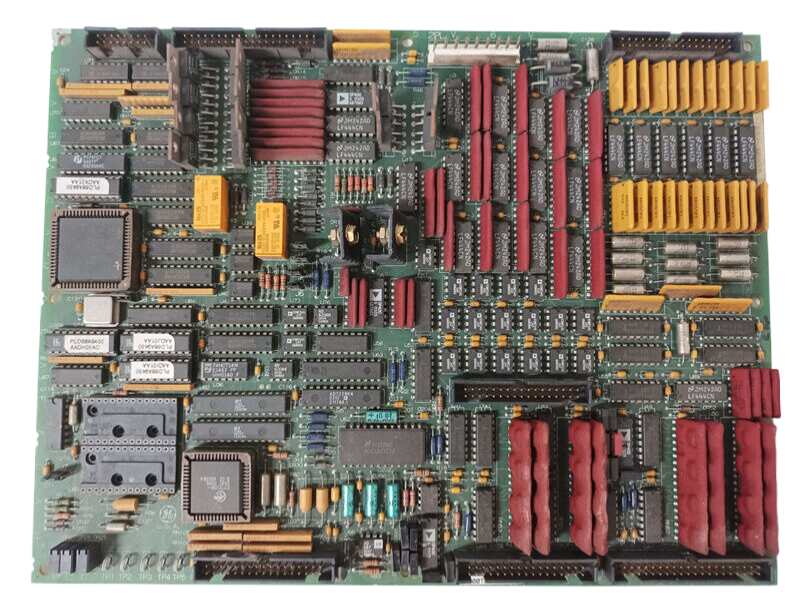

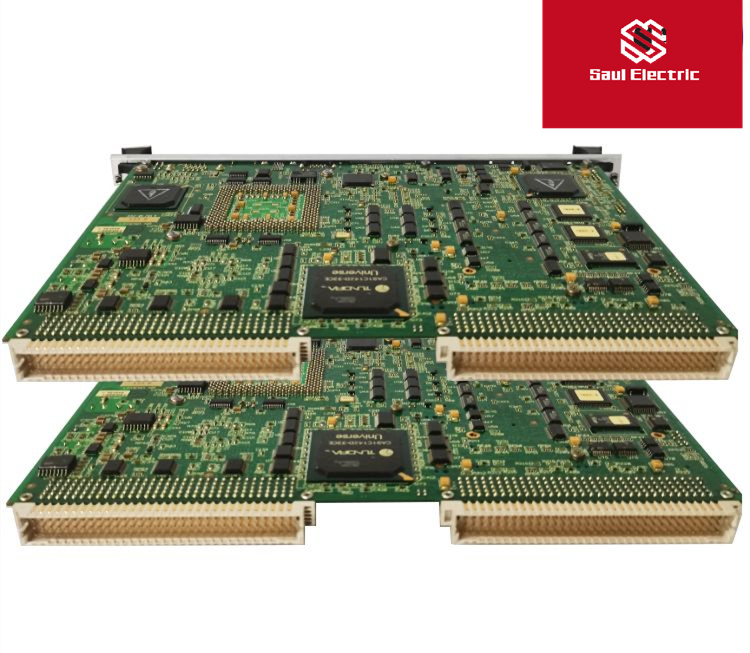

Brand:General Electric

Model:IS215VCMIH2CC

Module Category:VCMI H2C

Type:Control Board

Series:Mark VI Speedtronic

Functionality:VME Communications Interface

Revision Status:Twice Revised

Hardware Components:[“Customizable Jumper Settings”]

Dimensions:L x W x H (mm)

:167 x 148 x 55

Weight:0.6 kg

Compatibility:Mark VI Turbine Control Systems

Engineered with robust materials, the GE IS215VCMIH2CC Control Board ensures reliability and durability in harsh industrial environments. Its advanced microcontroller architecture supports a wide range of industrial protocols, enabling seamless communication with other system components.

With an operating temperature range of -40°C to 85°C, this control board is designed to withstand extreme environmental conditions, making it suitable for applications in diverse industries such as manufacturing, energy, and transportation.

Featuring a low power consumption of just 5W, the GE IS215VCMIH2CC Control Board optimizes energy usage without compromising performance, contributing to cost-effective and sustainable operations.

The inclusion of 128KB Flash Memory allows for ample storage capacity for system configurations, data logs, and firmware updates, ensuring flexibility and adaptability in managing complex industrial processes.

Equipped with RS-485, CANopen, and Modbus communication protocols, this control board facilitates efficient data exchange and control over devices within the system, enhancing operational efficiency and system integration.

Reviews

There are no reviews yet.