Description

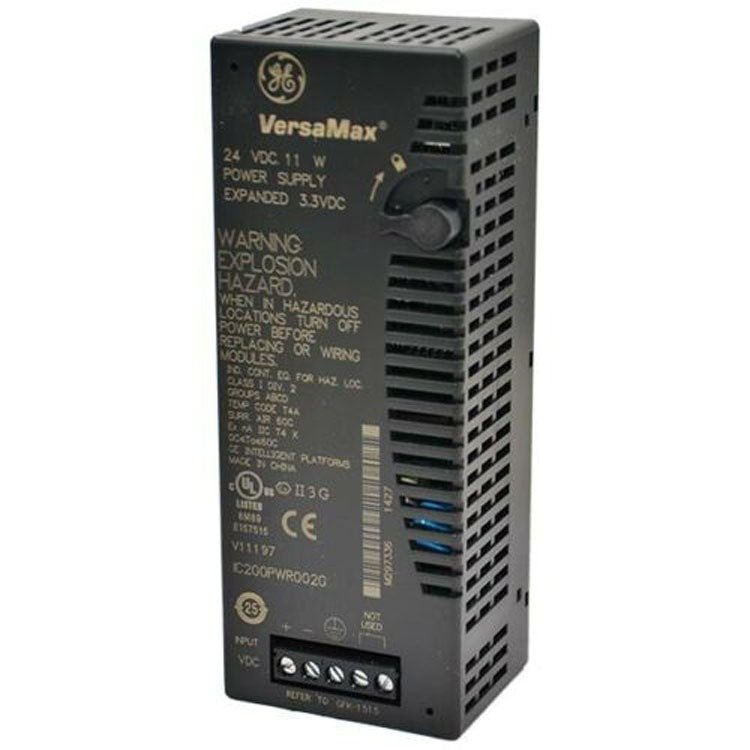

Manufacturer:GE-FANUC

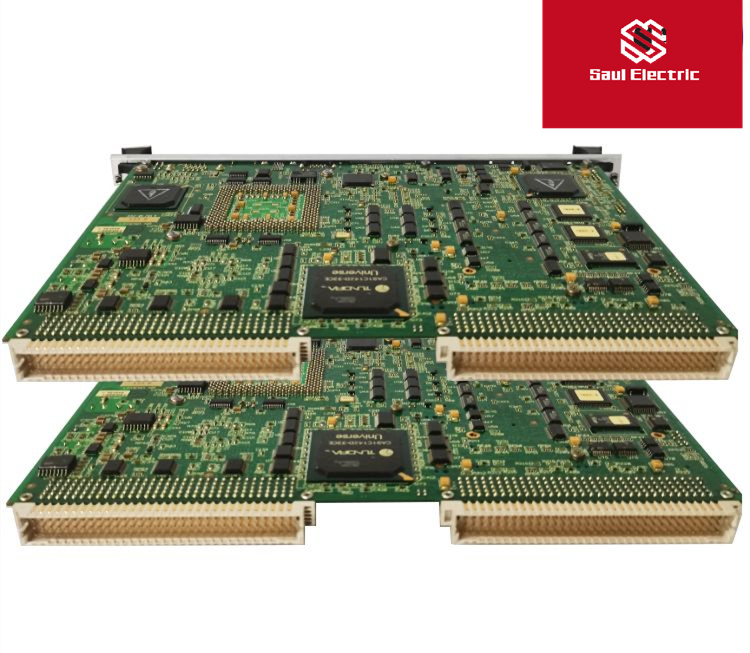

Part Number:DS200PCCAG6ADB

Functional Acronym:PCCA

Functional Description:Power Connect Card

PCB Coating:Normal Coating

Functional Revision:Revision 1A, Revision 2D

Artwork Revision:B

Instruction Manual:GEI-100161

Compatibility:DC2000 series

Interface Type:Interface between DC2000 drive assembly and SCR power bridge

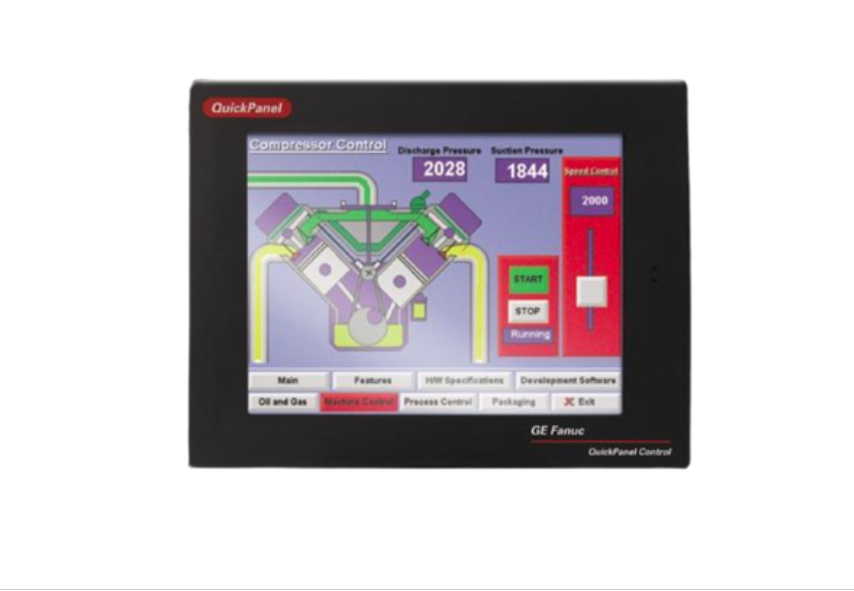

Communication Protocols:Supports standard communications

Memory Capacity:64MB user memory, 64MB flash memory

Processor:Pentium III CPU at 300MHz, 700MHz or 1.8GHz

Network Interface:Embedded 10/100 Mbps self-adaptive half/full-duplex Ethernet

Redundancy:Double machine hot standby with GE patented mirrored memory technology for synchronization

Data Transfer Rate:Up to 2.1Gbps synchronization rate

Remote I/O Connection:Ethernet or optical fiber options

Series Compatibility:Compatible with existing GE Fanuc control systems

Upgrade Capability:Controller upgrade without disrupting cabinet wiring

The GE-FANUC DS200PCCAG6ADB is engineered for seamless integration with the DC2000 series, offering enhanced functionality and reliability in industrial automation systems. This Power Connect Card is designed to optimize performance and reduce downtime by facilitating efficient communication between the drive assembly and the power bridge.

Featuring a robust Pentium III processor, the DS200PCCAG6ADB ensures fast processing and data handling capabilities, making it ideal for applications requiring high-speed data transfer and responsive system operation.

With support for multiple communication protocols, including Ethernet, this card ensures compatibility with various networking standards, enabling flexible and efficient data exchange across different devices within the industrial environment.

The embedded Ethernet interface supports both half and full duplex modes, allowing for versatile network configurations and ensuring reliable data transmission speeds.

For enhanced system resilience, the DS200PCCAG6ADB incorporates GE’s patented mirrored memory technology, providing synchronized operations and ensuring smooth system transitions during maintenance or upgrades, thus minimizing operational disruptions.

Reviews

There are no reviews yet.