Description

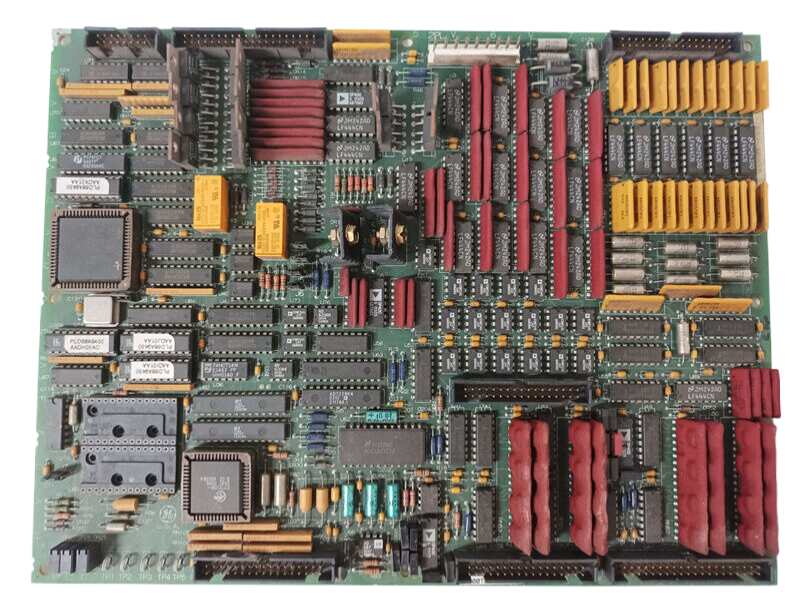

GE DS200TCQAG1BHF Gas turbine card

Main business of the company: :

Imported PLC module, programmable controller, servo control system, and DCS spare parts, etc.

For example, ABB, AB, GE, Bently, FOXBORO.MOTOROLA. XYCOM.HONEYWELL. TRICONEX.SCHNEIDER. REXROTH. YOKOGAWA.KUKA.OVATION.HIMA. Etc.

Characteristics of DCS

(1) Strong control function. Complex control laws can be realized, such as cascade, feedforward, decoupling, adaptive, and nonlinear control. Sequence control is also possible.

(2) High system reliability.

(3) CRT operation station has a good man-machine interface.

(4) The software and hardware adopt modular building block structure.

(5) The system is easy to develop.

(6) With configuration software, programming is simple, easy to operate.

(7) Have a good passion.

The components of PLC control cabinet generally include:

1: Air switch: a general air switch, this is the power control of the entire cabinet. Believe that every cabinet must have one thing.

2: PLC: This should be selected according to the needs of the project. For example, if the project is small, it can directly be an integrated PLC, but if the project is relatively large, it may need modules, card type, but also may need redundancy (that is, two sets of alternate use).

3:24 VDC power supply: a 24VDC switching power supply, most of the PLC comes with 24VDC power supply, according to whether it is really needed to decide whether to use this switching power supply.

4: Relay: Generally, PLC can directly send instructions to the control loop, but it may also be transferred by the relay. For example, if your PLC outlet is charged at 24VDC, but the diagram in your control loop requires the PLC node to be 220VAC, then you must add a relay to the PLC outlet, that is, the relay operates when the command is issued, but then let the node of the control loop connect to the normally open or closed point of the relay. The use of relays is also selected according to the situation.

5: Terminal: This must be the best thing in every cabinet according to the number of signals can be configured. If it is just a simple PLC control cabinet basically needs these things, if you also need to have other things in the control cabinet, it depends on the situation. For example, if you need to power some on-site meters or small control boxes, you may need to increase the number of air switches. Or if you want your PLC to connect to your PC, you may need to add switches or something. It depends.

PLC control cabinet can complete equipment automation and process automation control, to achieve the network function, strong, scalable, strong anti-interference characteristics, is the core and soul of modern industry. PLC control cabinet, frequency conversion cabinet, etc. can be tailored according to user requirements to meet user requirements, and can be matched with man-machine interface touch screen, to achieve easy operation. The device can transmit data with DCS bus modbus, profibus and other communication protocols. Industrial computer, Ethernet and other control and monitoring.

GE DS200TCQAG1BHF

GE DS200TCQAG1BHF

Main business of the company: :

Imported PLC module, programmable controller, servo control system, and DCS spare parts, etc.

For example, ABB, AB, GE, Bently, FOXBORO.MOTOROLA. XYCOM.HONEYWELL. TRICONEX.SCHNEIDER. REXROTH. YOKOGAWA.KUKA.OVATION.HIMA. Etc.

57bed632c38effdf0fc966f7af730ee5_u=3584330877

Characteristics of DCS

(1) Strong control function. Complex control laws can be realized, such as cascade, feedforward, decoupling, adaptive, and nonlinear control. Sequence control is also possible.

(2) High system reliability.

(3) CRT operation station has a good man-machine interface.

(4) The software and hardware adopt modular building block structure.

(5) The system is easy to develop.

(6) With configuration software, programming is simple, easy to operate.

(7) Have a good passion.

The components of PLC control cabinet generally include:

1: Air switch: a general air switch, this is the power control of the entire cabinet. Believe that every cabinet must have one thing.

2: PLC: This should be selected according to the needs of the project. For example, if the project is small, it can directly be an integrated PLC, but if the project is relatively large, it may need modules, card type, but also may need redundancy (that is, two sets of alternate use).

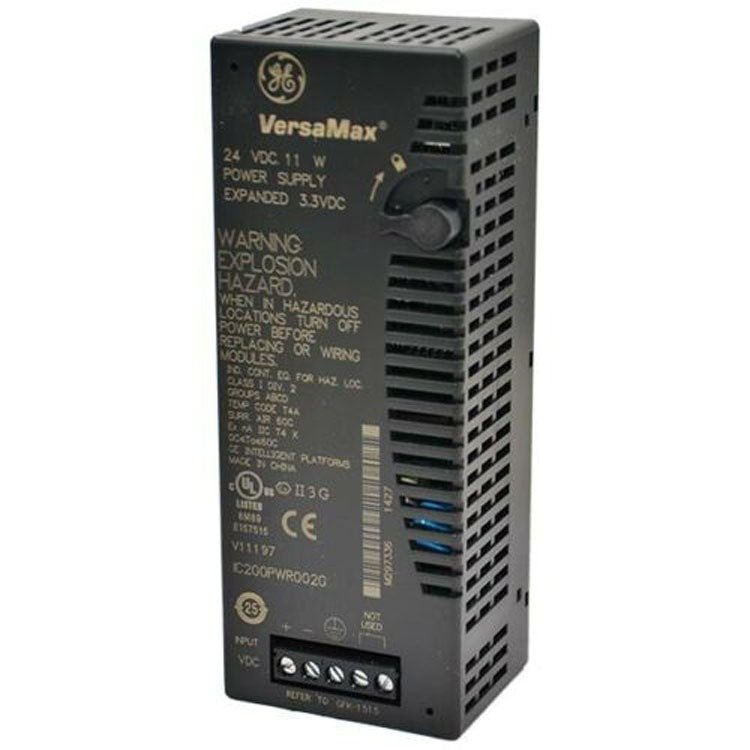

3:24 VDC power supply: a 24VDC switching power supply, most of the PLC comes with 24VDC power supply, according to whether it is really needed to decide whether to use this switching power supply.

4: Relay: Generally, PLC can directly send instructions to the control loop, but it may also be transferred by the relay. For example, if your PLC outlet is charged at 24VDC, but the diagram in your control loop requires the PLC node to be 220VAC, then you must add a relay to the PLC outlet, that is, the relay operates when the command is issued, but then let the node of the control loop connect to the normally open or closed point of the relay. The use of relays is also selected according to the situation.

5: Terminal: This must be the best thing in every cabinet according to the number of signals can be configured. If it is just a simple PLC control cabinet basically needs these things, if you also need to have other things in the control cabinet, it depends on the situation. For example, if you need to power some on-site meters or small control boxes, you may need to increase the number of air switches. Or if you want your PLC to connect to your PC, you may need to add switches or something. It depends.

PLC control cabinet can complete equipment automation and process automation control, to achieve the network function, strong, scalable, strong anti-interference characteristics, is the core and soul of modern industry. PLC control cabinet, frequency conversion cabinet, etc. can be tailored according to user requirements to meet user requirements, and can be matched with man-machine interface touch screen, to achieve easy operation. The device can transmit data with DCS bus modbus, profibus and other communication protocols. Industrial computer, Ethernet and other control and monitoring.

General details 1.jpg

Finally, Mei Lixin, CEO of Jiangsu Dajiang Petroleum Technology Co., Ltd. in Jiangyin, China, reports that his eight-year-old company has developed a new method – composite heat carrier generator (CHCG) – to increase oil and gas production from fractured Wells and designed an explosion-proof version for use on offshore platforms. The company increases production for China’s biggest oil and gas companies, including petrochina, CNOOC and Sinopec.

“The DS200DCFBG1BLC has three conventional enhanced oil recovery methods — thermal recovery, gas injection and chemical injection. We think there is a fourth approach that combines the original three approaches, “Li said. “It is based on mixing fuel, air and water in a sealed chamber and injecting them, almost like a rocket engine, into the target reservoir at extremely high temperatures and pressures, which are mostly in light, heavy and low-permeability oil fields.”

Lixin added that Jiangsu Dajiang’s CHCG equipment uses a pressure of about 30 megapascals (mPa) and a temperature range of 120°C to 350°C. Its complex heat carrier (CHC) is mainly carbon dioxide, nitrogen, steam, and chemicals, with a flow rate of approximately 1,200 standard cubic meters (Nm3) to 3,600 Nm3 into Wells 300 to 3,000 meters deep. “The three main components of our CHCS greatly dilute the oil in the reservoir, making it easier to extract and producing zero carbon emissions,” Lixin explained. Also, less than 2 percent of the oxygen remains in our process, which makes it much safer.”

DS200DCFBG1BLC To reliably control and maintain its innovative CHCG system, Lixin added that Jiangsu Dajiang chose to employ a variety of Rockwell Automation’s ControlLogix PLCs, software and other components, even implementing them in explosion-proof cabinets used on offshore oil RIGS. “CHCG requires a highly reliable control system, good maintenance, remote access and global support, so Rockwell Automation was able to provide us with a turnkey system that solved our previous problems and enabled our mean time to failure (MTBF) to exceed 200,000 hours,” Lixin said.

DS200DCFBG1BLC So far, CHCG is allowing oil companies serving Jiangsu Dajiang to extract more oil and gas, Li Xin reports. “In heavy oil fields, CHC injection improves recovery by 10 to 15 percent compared to conventional steam injection,” Li said. “As a result, the oil productivity per well is 6.6 times the original productivity. In addition, the Nanpu heavy oil field is the first application of CHCG offshore. It meets the requirements of explosion protection and operates stably, increasing oil production from 10 Nm3 to 66 Nm3 per day.”

Reviews

There are no reviews yet.