Description

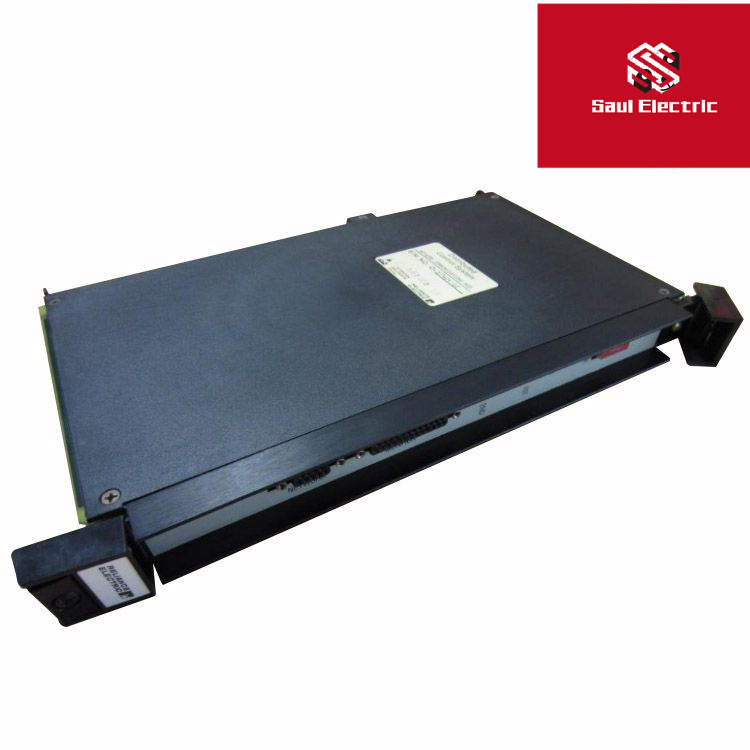

The BENTLY Pressure Monitor 3500/77M-03-00, as a mechanical measuring instrument accessory for TSI systems, offers a range of notable features and specifications. The following is a detailed description of the pressure monitor:

Basic information

Model: 3500/77M-03-00

Brand: BENTLY

Applications: Suitable for a variety of TSI systems requiring accurate monitoring of cylinder pressure

Main feature

High precision measurement: The use of high-quality electronic components and advanced production processes to ensure that the cylinder pressure is measured with high precision, so as to ensure the normal operation of the cylinder.

Real-time monitoring: It can monitor the pressure of the cylinder in real time, and convert the pressure signal into an electrical signal, which is transmitted to the PLC or DCS system for data processing and control.

Easy configuration and maintenance: Supports a variety of configuration options, easy to configure and expand according to actual requirements. At the same time, it provides a friendly user interface and rich programming software, which is easy for users to operate and maintain.

Versatility: Support a variety of communication interfaces, such as Ethernet, Profinet, etc., to facilitate data transmission and control.

Strong adaptability: Adapt to different environments and application scenarios, including complex environments such as high temperature, low temperature, and strong magnetic field.

Technical specification

Number of channels: 4-channel monitor accepts input from Bentley Nevada approved pressure sensors.

Frequency response: It is not explicitly given, but based on its high-precision characteristics, it can be inferred that it has a high frequency response capability.

Measurement variables: including ejecting rod compression, peak rod tension, rod reversal degree, etc., these parameters are closely related to cylinder pressure operation.

Pressure accuracy: 0.5% accuracy in the range of 0.5 to 10.0 volts at 77°F. In the range of 22 to 150°F, from 0.5 to 10.0 volts is 1.0%.

Front panel LED: Includes OK, TX/RX, and Bypass status indicators, which helps you quickly understand the working status of the device.

Sensor power supply: 23.0± 0.8VDC, current limit: 24.5 mA.

Care and maintenance

Periodically check the appearance and connection of the cylinder pressure monitor to ensure that the power supply, signal and other lines are normal.

Clean the casing and internal components of the cylinder pressure monitor regularly to avoid dust and debris affecting its normal operation.

Periodically test the functions of the cylinder pressure monitor to ensure its normal operation.

Record the results of each inspection and test, and report any anomalies in time.

| WOODWARD | WOODWARD 8800-1001 |

| GE | GE DM5E Basic |

| BENTLY | 330104-00-06-10-02-00 |

| BENTLY | 330130-080-01-00 |

| BENTLY | 330180-90-00,9 meter |

| BENTLY | 330730-080-01-00 |

| BENTLY | 330854-080-24-00 |

| BENTLY | 330851-02-000-030-10-00-05 |

| ABB | 70EA05a-E |

| BENTLY | \330180-51-00 |

| BENTLY | 330130-040-01-00 |

| BENTLY | 330105-02-12-10-02-00 |

| ABB | FS450R12KE3/AGDR-71C |

| ABB | DSMB-01C |

| ABB | DSAB-01C |

| ABB | DSMB-02C |

| ABB | RINT5611C |

| ABB | RMIO-02C |

| ABB | ZINT-571 |

| FANUC | A06B-6400-H002 |

| SST | SST-PB3-CLX-RLL |

| SST | SST-PB3-CLX-RLL |

| GE | EPXPNS001 |

| ICS TRIPLEX | T9100 |

| GE | VMIPCI-5565 |

| EPRO | PR9376/010-011 |

| EMERSON | A6500-UM |

| KONGSBERG | KONGSBERG 303088 |

| SELCO | M2100.0020 |

| ABB | SDCS-CON-2A |

| ABB | ARC093AE01 HIEE300690R0001 |

| YOKOGAWA | Cp451-50 S2 |

| A-B | 2080-L50E-48QBB |

| ELAU | MC-4/11/22/400 |

Reviews

There are no reviews yet.