Description

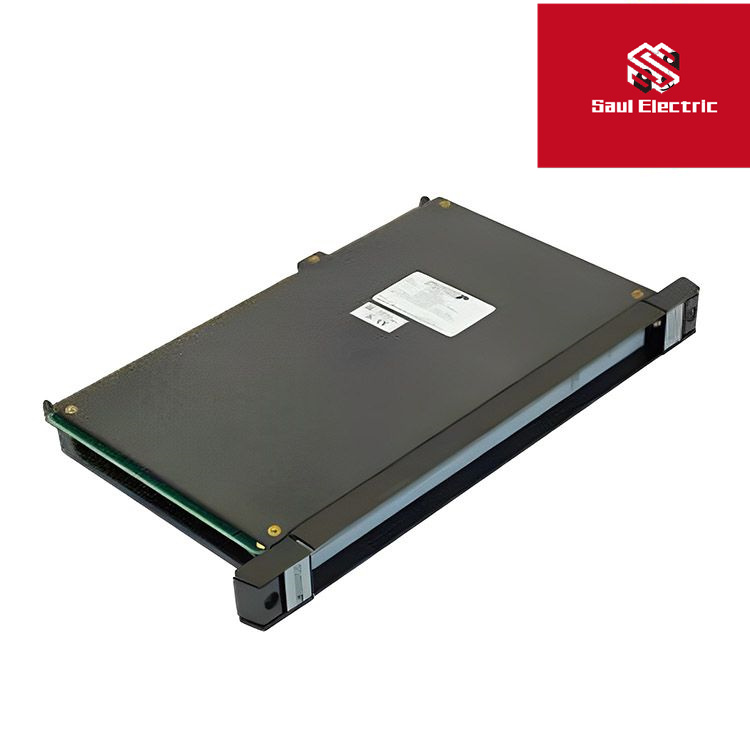

Operating Temperature:-40°C to +100°C

Sensing Range:0.1 to 10 mm

Sensitivity:1 μm/1 mm

Output Type:4-20 mA

Input Power:12 to 40 VDC

Communication Protocol:HART

Material:Stainless Steel

Environmental Rating:IP65/IP67

Mounting Type:Vibration Isolated

Operating Frequency:50 Hz

Power Consumption:Max. 2 W

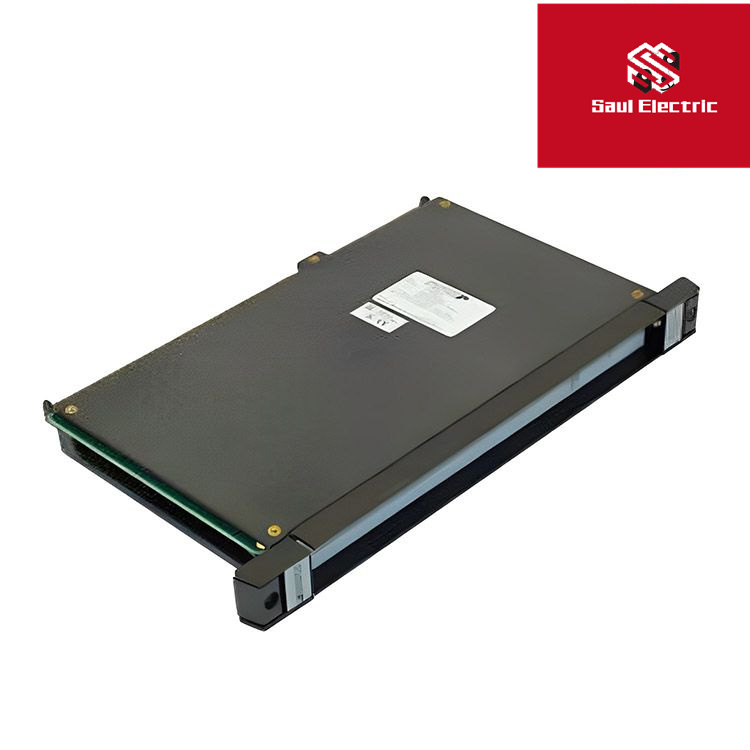

Engineered for precision and durability, the Bently Nevada 990-10-XX-01-05 MOD:285269-01 offers unparalleled reliability in challenging industrial environments. Its high-frequency response allows for sensitive detection of machine vibrations, enabling proactive maintenance strategies to minimize downtime.

The advanced design ensures compatibility with a wide range of industrial control systems through its MODBUS communication protocol, simplifying integration into existing monitoring solutions.

Manufactured from robust materials, this vibration transmitter withstands extreme temperatures (-40°C to +125°C) and harsh conditions, ensuring continuous operation without failure.

With its IP67 rating, the device is protected against dust and water ingress, guaranteeing reliable performance even in wet or dusty industrial settings.

The Bently Nevada 990-10-XX-01-05 MOD:285269-01 is not just a sensor; it’s a tool for enhancing operational efficiency, reducing maintenance costs, and safeguarding critical assets in your facility.

Reviews

There are no reviews yet.