Description

Model Number:330500

Sensor Type:Piezo-Velocity

Operating Range:2 mm

Sensitivity:1 um

Output Type:Voltage

Installation Type:Non-contact

Operating Temperature:-40°C to +100°C

Package/Casing:Injection Molding

Characteristic:High Temperature Resistance

Termination Type:Gold Connector

Minimum Packaging:1 unit

Application Areas:Industrial Machinery, Rotating Equipment

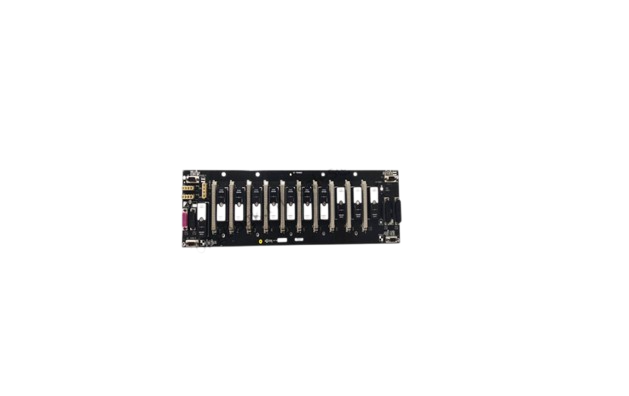

Engineered for durability and precision, the Bently Nevada 330500 Velomitor Piezo-Velocity Sensor integrates seamlessly into your industrial machine monitoring system. Its compact, two-pin design allows for straightforward installation without compromising on performance.

Specifically tailored for machines with rolling-element bearings, this sensor excels in measuring vibrations in units of velocity, providing critical insights into machinery health and maintenance needs.

Crafted with high-quality materials and advanced manufacturing techniques, the sensor withstands harsh industrial environments, ensuring longevity and reliability over extended periods of use.

The sensor outputs precise data, facilitating accurate analysis through your existing monitoring software or systems, enhancing predictive maintenance capabilities and reducing downtime.

With a delivery time of 8-10 weeks from manufacture, our team prioritizes quick response to orders, ensuring minimal disruption to your operational schedule.

Reviews

There are no reviews yet.