Description

Sensor Type:Piezo-accelerometer

Model:330500-02-04

Series:3300XL

Operating Voltage:Not specified

Output Frequency:30 kHz

Certification:Certified Product

Custom Processing:Yes

Item Number:72471-BC

Order Number:PWA90482-01

Installation Type:Rugged, 2-pin

Output Type:Integrating

Sensing Range:Not specified

Sensitivity:1um

Operating Temperature:Not specified

Package/Casing:Injection molding

Termination Type:Gold connector

Minimum Number of Packages:1

Application Areas:Industrial control, equipment monitoring

Item Code:PWA90482-01

Certified Product Code:72471-BC

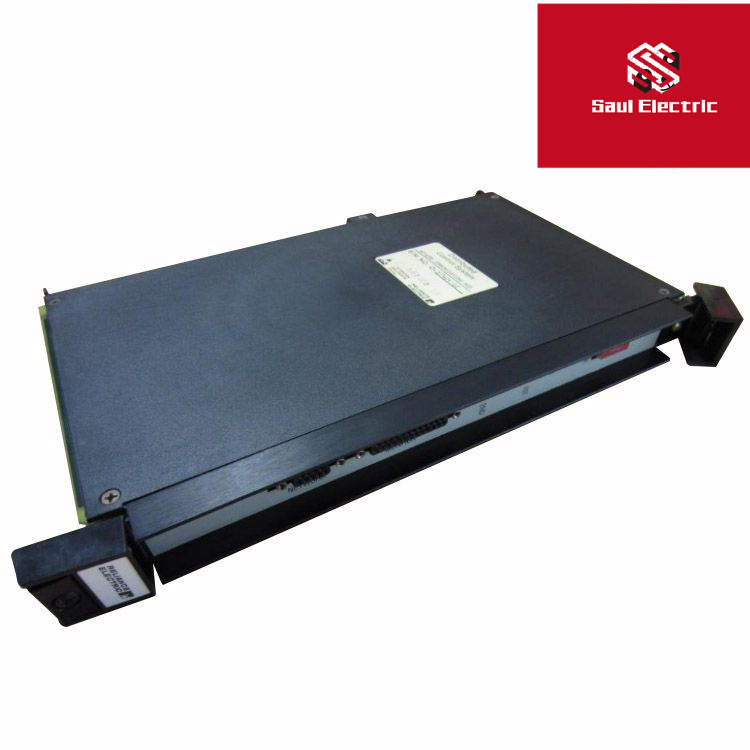

Engineered for durability and reliability, the Bently Nevada 330500-02-04 Velomitor Piezo-Velocity Sensor ensures continuous operation in harsh industrial conditions.

This sensor integrates seamlessly with advanced monitoring systems, providing real-time velocity data for predictive maintenance.

Crafted from high-grade stainless steel, it withstands extreme temperatures, humidity, and corrosive environments, ensuring longevity and performance.

With its gold-plated connector and rigid mounting option, the sensor offers secure and reliable connections, minimizing the risk of disconnection or damage.

Capable of measuring velocities with an accuracy of ± 5% of the reading, this sensor delivers highly precise data, crucial for effective machinery health management.

Reviews

There are no reviews yet.