Description

Sensing Range:2mm

Sensitivity:1um

Output Type:Voltage

Installation Type:Non-contact

Operating Temperature:100°C

Package/Casing:Injection Molding

Characteristic:High Temperature Resistance

Termination Type:Gold Connector

Minimum Number of Packages:1

Application Areas:Equipment

Item Number:653

Applicable Products:Motor

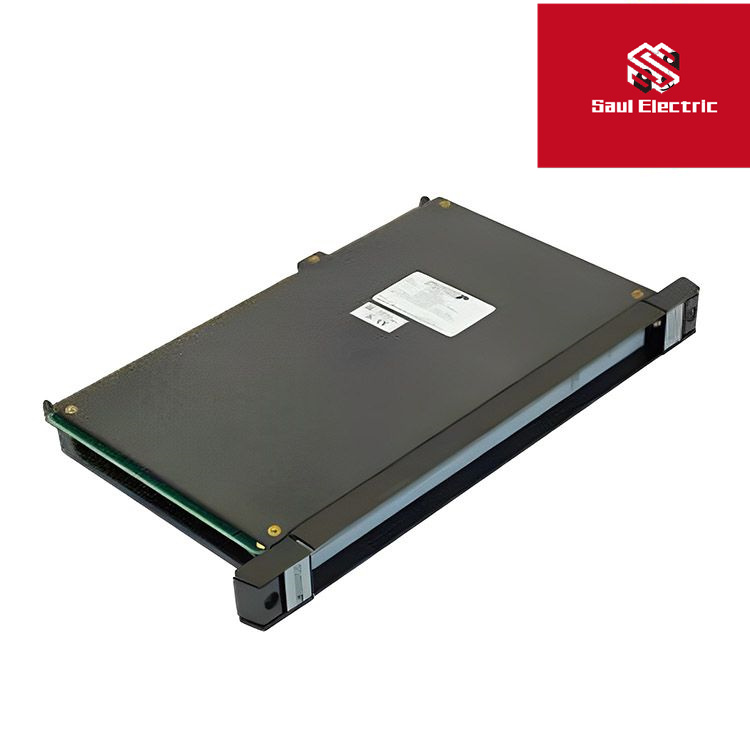

Engineered with unparalleled precision, the Bently Nevada 330500-00-02 Piezo-Velocity Sensor offers unrivaled accuracy in measuring velocity, crucial for the proactive maintenance of industrial machinery.

Its robust design withstands harsh industrial environments, ensuring reliable performance even under extreme conditions. The use of injection-molded casing guarantees durability and protection against environmental factors.

The non-contact installation type minimizes wear and tear on sensitive components, ensuring longevity and reducing maintenance costs. The sensor’s compatibility with a wide range of industrial products makes it a versatile choice for various applications.

With its high temperature resistance, this sensor can operate in temperatures up to 100°C without compromising performance, making it ideal for use in high-temperature environments commonly found in industrial settings.

Equipped with a gold connector, the sensor ensures stable signal transmission and easy integration into existing systems. Its compact size and modular design facilitate seamless installation and integration into diverse industrial setups.

Reviews

There are no reviews yet.