Description

Model:3300/25

Sensor Type:Dual Accelerometer

Monitoring Range:0 to 25 g

Accuracy:±0.5% F.S.

Sampling Rate:Up to 2 kHz

Operating Temperature:-40°C to +70°C

Power Supply:9 VDC

Dimensions:88mm x 56mm x 35mm

Weight:Approx. 100g

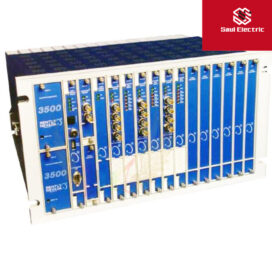

The Bently Nevada 3300/25 Dual Accelerometer Monitor is a state-of-the-art solution designed for continuous monitoring of high-speed rotating machinery, providing accurate vibration measurements essential for condition-based maintenance strategies.

Featuring dual accelerometer inputs, this monitor allows for comprehensive analysis of multiple machines or different parameters on the same machine, ensuring no detail is overlooked.

With its wide operating range and exceptional accuracy, the Bently Nevada 3300/25 is capable of detecting even subtle changes in machinery health, enabling timely interventions to prevent unexpected downtime and costly repairs.

The device is equipped with advanced signal processing algorithms that filter out noise, focusing on critical vibration data, thus aiding in early detection of potential issues like imbalance, misalignment, or bearing defects.

Offering a compact yet robust design, it is suitable for installation in various industrial environments, from power plants and manufacturing facilities to mining and oil & gas operations, ensuring reliable performance under extreme conditions.

Integrating seamlessly with other Bently Nevada systems and third-party SCADA platforms through its 4 to 20 mA analog output, the monitor facilitates easy integration into existing infrastructure, streamlining maintenance workflows and enhancing overall operational visibility.

Reviews

There are no reviews yet.