Description

Sensor Compatibility:Up to 4 vibration/position/speed inputs

Temperature Monitoring:4 temperature inputs

Data Conversion:24-bit ADC conversion

Event Logging:200-entry event list

Alert Customization:Independent Alert and Danger setpoints

Relay Outputs:Up to 6 relay outputs programmable for diverse applications

Recorder Outputs:Up to 4 configurable 4-20 mA recorder outputs

Operating Range:Wide temperature and humidity tolerance

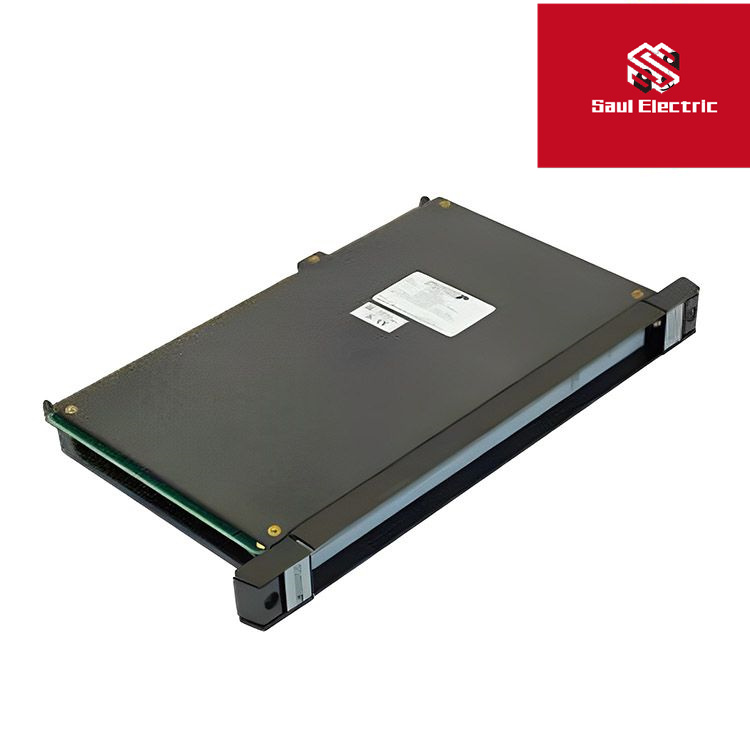

The Bently Nevada 1900/65 is a state-of-the-art solution for comprehensive machinery health monitoring, providing real-time insights into the operational status of industrial equipment. This system is equipped with advanced signal processing algorithms that enable precise detection of subtle changes in vibration patterns, temperature fluctuations, and other critical parameters that can indicate impending equipment failures.

Featuring eight input channels, it supports a variety of measurement types including vibration, position, speed, and temperature, making it suitable for a wide range of industrial applications from turbines to pumps. The high-speed 24-bit Analog-to-Digital Converter (ADC) ensures accurate data acquisition at up to 10 kHz sampling rates, crucial for timely analysis and decision-making.

The system is designed with user-friendliness in mind, offering a backlit LCD display for easy viewing under various lighting conditions. It includes four configurable relay outputs, allowing for customized alert systems based on predefined thresholds. The internal event log with 200 entries helps track historical data and monitor equipment performance over time.

Operating within a broad temperature range from -40°C to +70°C, the Bently Nevada 1900/65 is built for durability and reliability in harsh industrial environments. It supports both 12 VDC and 24 VDC power supplies, ensuring flexibility in installation and maintenance.

With its robust design and advanced monitoring capabilities, the Bently Nevada 1900/65 is an indispensable tool for enhancing safety, reducing downtime, and optimizing maintenance schedules in modern manufacturing and industrial operations.

Reviews

There are no reviews yet.