Description

Main features of the product: self detection and fault-tolerant design, can be configured with multiple redundancies, ranging from adding a second fully redundant power supply to a complete triple modular redundancy (TMR) configuration. It can be used for selected channels as well as all channels, fully meeting critical task applications and seamlessly connecting with the Bentley System1 status monitoring and diagnostic analysis software platform.

The communication gateway module can communicate with factory control and automation systems, and is designed to comply with the American Petroleum Institute standard API 670; Design to comply with the API 618 standard for reciprocating compressor applications; Certified with DNV and Class NK certificates in the field of offshore applications; Certified by Canadian Standards Association (CSA), Factory Mutual Aid (FM), GOST, ATEX, and CE.

The Bently 3500 vibration monitoring and protection system in the United States provides online monitoring functionality.

The bently3500 system can monitor the vibration of large rotating machinery such as steam turbines, water turbines, fans, compressors, turbine expanders, electric motors and generators, excitation machines, gearboxes, water pumps, etc

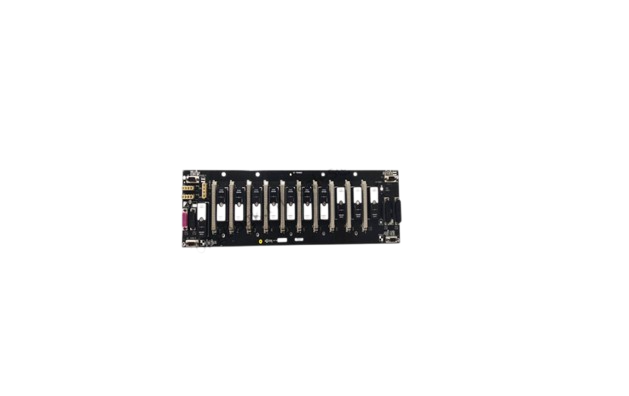

Bently 3500/05 Instrument Frame

Bently 3500/15 power supply

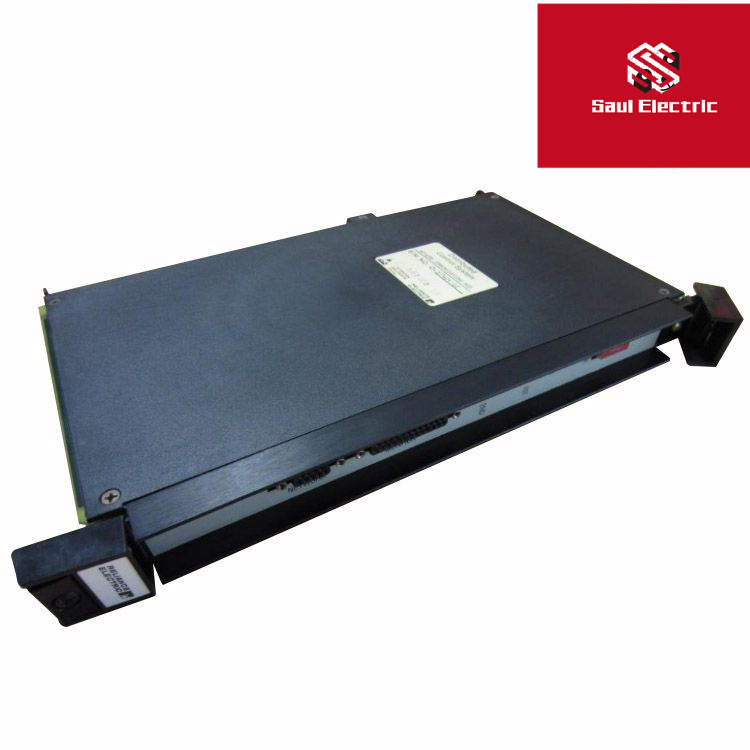

Bently 3500/20 Framework Interface Module

Bently 3500/22 framework interface module.

Bently 3500/25 Keyphasor Module

Bently 3500/01 Framework Configuration Software

Bently 3500/40 monitor module channel types: radial vibration, axial displacement, eccentricity, differential expansion

Bently 3500/42 monitor module channel types: acceleration, velocity, shaft vibration

Bently 3500/45 monitor module channel types: axial displacement, differential expansion, inclined differential expansion, shell expansion, valve position.

Reviews

There are no reviews yet.