Description

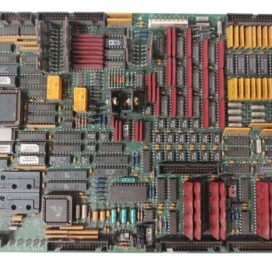

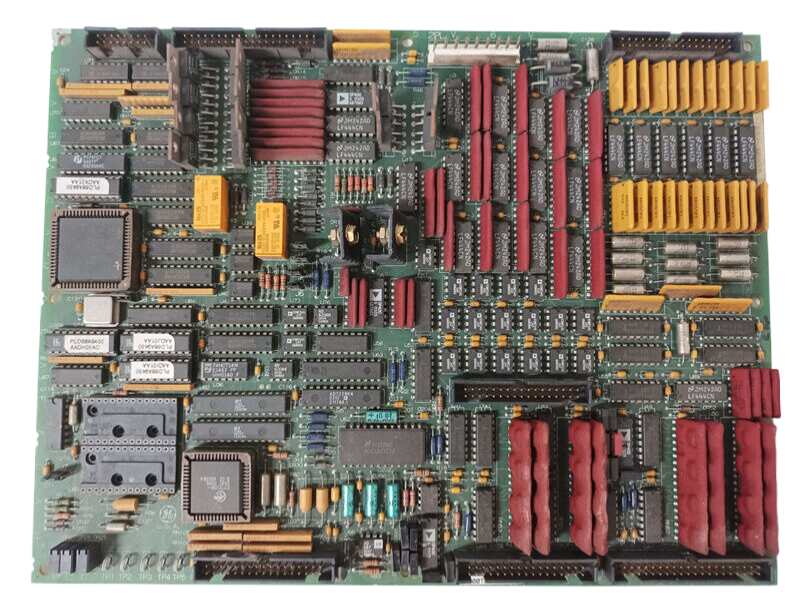

American GE IS220PAICH2A analog input/Output gas turbine module3

What does a heavy gas turbine do: engines for large ships and the like. Gas turbine mainly used for power generation and Marine power

We have a large stock of control system components. We also have many new hardware and discontinued spare parts to help support your existing control system

If you find that other suppliers have quoted lower prices for the same products, we are also willing to give you further discounts by reference to their prices.

We will choose the best and cheapest carrier.

We will track the shipment time after time until it reaches the customer.

♥ Different functions of the control cabinet inside the control components are not the same, but it has its own control role, for most just engaged in industrial automatic control, it is estimated that it will take a period of time to understand these control components.

★ Frequency converter

As a control motor debugging device, frequency converter is widely used.

★PLC device

PLC is mainly used in industrial automatic control, the complex wiring maximum simplification, complete in accordance with the mechanical, electrical equipment automatic program control input, output and at one go.

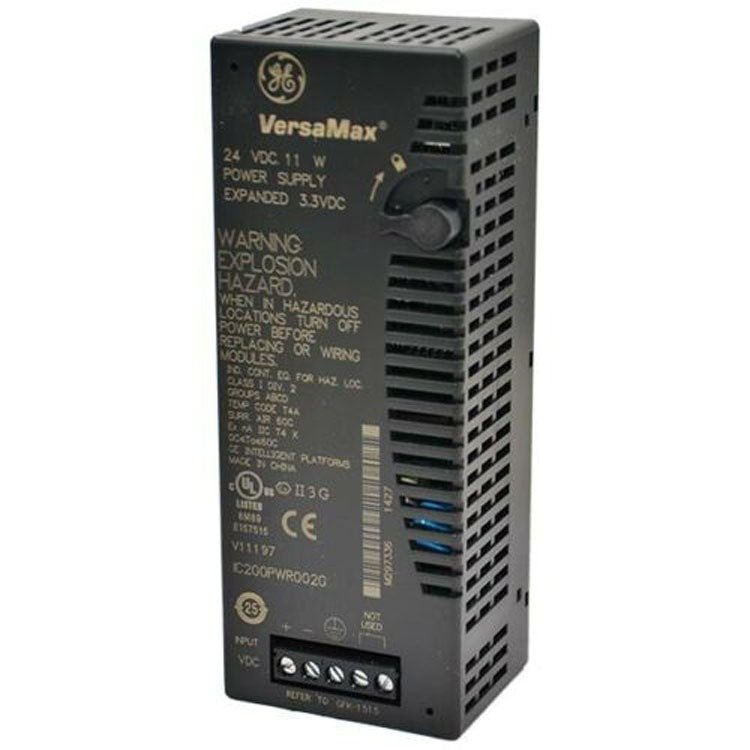

★ switching power supply

Switching power supply is a DC power supply that provides automatic control.

★ isolation transformer

Isolation transformer is a device that provides operating voltage in the distribution cabinet and reduces interference sources.

Current transformer

The main function of the current transformer is to cooperate with the measuring instrument to measure the actual working current in the line

★ transfer switch

The transfer switch provides different measurement results and control functions. Includes a reverse switch for simple control of motor forward and reverse rotation.

★ Button

Button function and use is very wide, such as lathe starting and stopping, positive and reverse, etc.; The start, stop, rise, fall, front, back, left, right, slow or fast running of the tower crane need to be controlled by buttons. Button is a kind of manual control of the master electrical appliance, mainly used to issue operation commands, switch on or off the control circuit, control the operation of mechanical and electrical equipment.

★ indicator light

The indicator light has a variety of colors, common red, green, yellow, white and other colors. The role of the indicator has three: one is to indicate the running and stopping state of the electrical equipment; Second, monitor whether the power supply of the control circuit is normal; The third is to use the red light to monitor whether the trip circuit is normal, and the green light to monitor whether the closing circuit is normal.

★ time relay

Time relay plays the role of delay closing or breaking in the circuit. Time relay is divided into two kinds, one is power delay, the other is power delay.

★ photoelectric switch

There are many kinds of photoelectric switches, and their working principle is used to detect circuit signals according to their own structure. Photoelectric switch has been used in crop level detection, liquid level control, product counting, width discrimination, speed detection, fixed length shear, hole identification, signal delay, automatic door sensing, color label detection, punch and shear machine and security protection and many other fields.

★ Circuit breaker

The circuit breaker provides total power protection for the control cabinet, facilitates outage maintenance and protects the main circuit

★ mini circuit breaker

Circuit breakers are used to control the on-off circuit in the main circuit or control circuit. Small circuit breaker, play the role of overload protection or short circuit trip, among which, leakage protector in addition to the role of the ordinary circuit breaker, also has the function of leakage protection, when the leakage current occurs, the circuit breaker will trip to protect the safety of personnel.

Ac contactor

There are many kinds of AC contactors, but their functions are the same. It’s just the structure that’s different. Ac contactor should distinguish the voltage level of the coil, the commonly used AC contactor coil voltage is 24V, 36V, 110V, 220V, 380V and so on.

★ small intermediate relay

The number of small intermediate relay used in the PLC control loop is more, we must distinguish its auxiliary contact group composition when using. The auxiliary contact group is more, but also distinguish its coil voltage level, common DC24 volt, and 220 volt coil.

★ Fuse

The fuse includes the fuse holder and the fuse core, which is placed in the control loop in most cases to play the role of short circuit protection. When there is a short circuit fault, the fuse core capacity will be fused, the control loop disconnected.

★ Wiring terminal

Also known as the terminal, the terminal is mostly used in the control cabinet connecting the cabinet wiring to the field wiring conversion terminal, it has many forms, but its role basically plays the role of excessive connection.

★ travel switch

Travel switch is also called limit switch, it is often used in the reciprocating control loop, play a limit role or in place stop role. It has normally open, normally closed contacts and common points, when the mechanical device touches a arm, it will be connected with the contacts in the section, so as to control the electrical equipment. Travel switch variety, but the place is not the same, its function is exactly the same.

We have made a series of coke oven heating program and low water coke quenching automatic control program for users. The logic program of series heating and low water coke quenching automatic control is realized in AC800F controller, and the software is used to realize the logic switch of series heating/manual heating. At the same time, the position and size of coke quenching water valve are displayed. It lays a foundation for users to further explore the way of coke oven heating and quenching. We automatically adjust and control the liquid level of “regenerator”, “ammonia distillation tower”, “underground vent tank”, “oil vent tank” and “heat conduction oil outlet temperature”, “pipe furnace temperature” and other temperatures. Because the SP value (set value) of many regulating loops is an uncertain number, it needs to be different according to the requirements of different periods; In the design of PID regulation and manual/automatic switching, we design SP to track PV in manual mode, and adjust the process value according to the SP value in automatic mode, so that when the operator manually adjusts the process value to the appropriate time, switch to automatic and can immediately adjust the process value. To facilitate the operator to further explore ways to improve work efficiency. We have also made the cumulative calculation of process parameters such as “steam consumption”, “compressed air volume” and “new water consumption” for it, as well as automatic trend report and automatic daily report for up to 50 years. Factories can analyze the production process according to these report data, optimize the production process and constantly improve labor productivity. In the design of the software, we consider a variety of shortcuts on the operation screen, which is conducive to the user’s quick query of the required information. When the operator station, engineer station shut down one or all, as long as the process station does not stop, the system will not stop; The process station adopts the redundancy mode of dual-machine hot backup, and the system terminals are imported terminals, which reduces the failure rate, so the whole system is very safe. 5. At present, the operation of the system exceeds the design requirements. The designed annual output of the whole system is 1.2 million tons of coke/year. Under the condition of not having the operation conditions, the system has been put into operation and achieved the goal of two coke ovens reaching the production efficiency in 15 days. At the same time, it provides an effective control means, and the practice proves that the system has made contributions to improving labor productivity and economic benefits for users

Reviews

There are no reviews yet.