Description

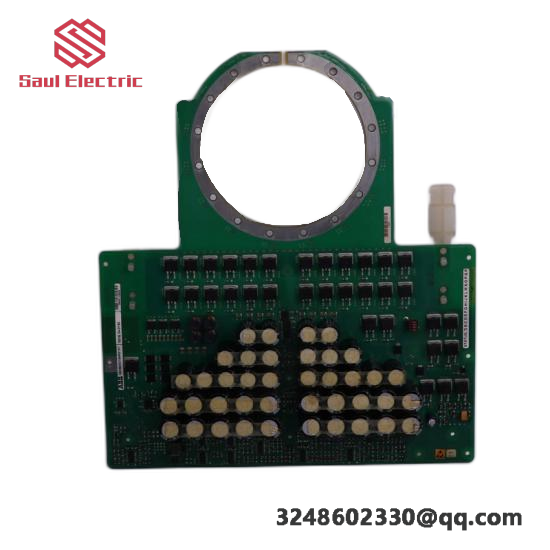

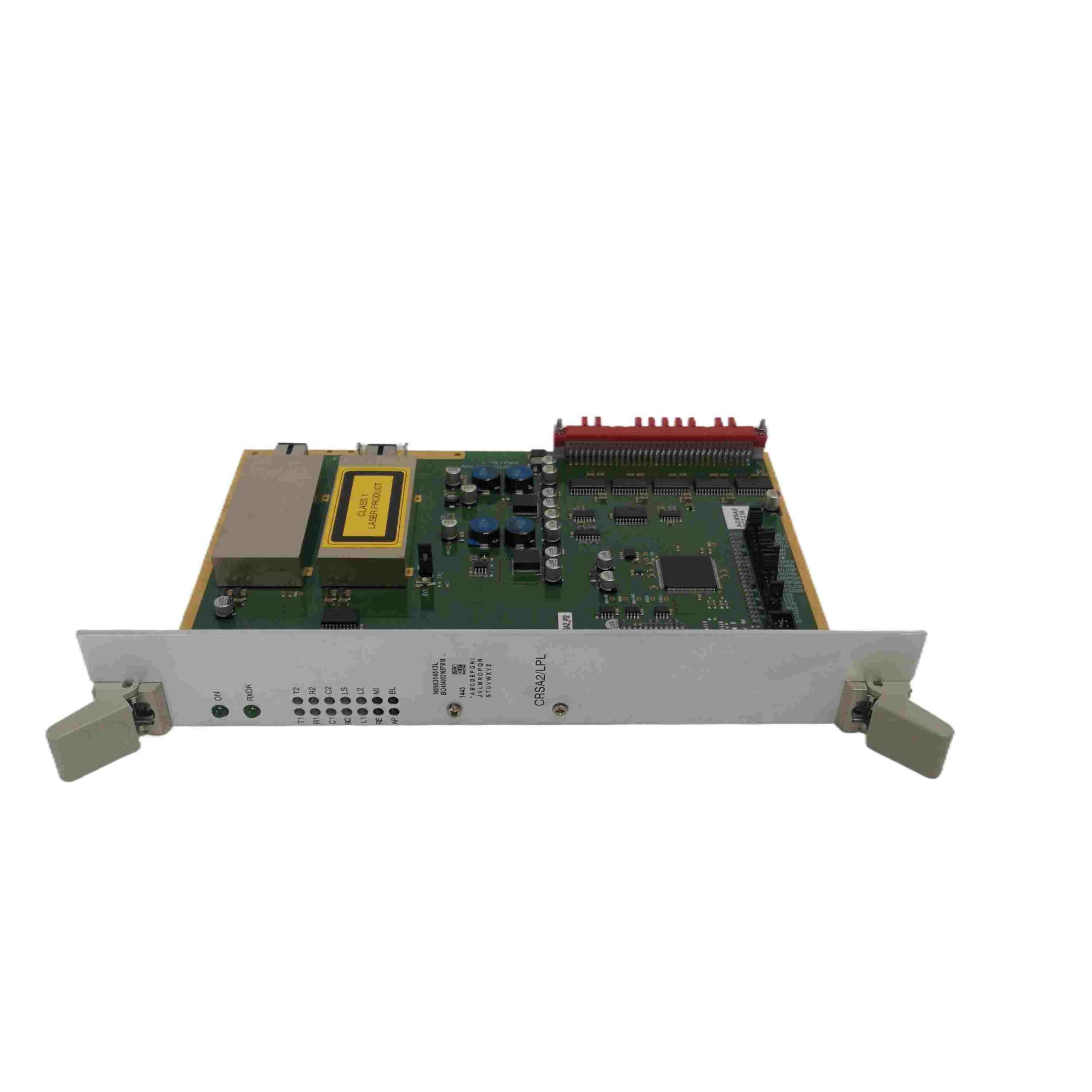

Type:Process Automation System

Model:P-HA-RPS-PEP 11012

Manufacturing Brand:ABB

Operating Voltage:24V DC

Communication Protocol:Modbus TCP/IP, Ethernet/IP

Processing Speed:0.1 ms

Power Consumption:15 W

Temperature Range:-20°C to +70°C

Humidity Range:5% to 95% non-condensing

Dimensions:170 mm x 140 mm x 80 mm

Weight:1.3 kg

Operating Environment:Indoor industrial use

Safety Standards:CE, UL, IEC

Certifications:ISO 9001, ISO 14001

The ABB P-HA-RPS-PEP 11012 is a state-of-the-art solution tailored for complex industrial environments, ensuring seamless integration with existing systems and rapid deployment.

Engineered with cutting-edge technology, this system offers unparalleled performance, enabling precise control over critical processes and real-time monitoring for enhanced operational reliability.

Featuring a robust design, the P-HA-RPS-PEP 11012 withstands harsh conditions without compromising on performance, making it suitable for applications across diverse industries including petrochemicals, power generation, and pharmaceuticals.

With its extensive communication capabilities, the system facilitates smooth data exchange with other components, streamlining workflows and improving overall productivity.

The ABB P-HA-RPS-PEP 11012 comes equipped with an intuitive user interface, simplifying setup and maintenance tasks, thus reducing downtime and minimizing operational complexities.

Reviews

There are no reviews yet.