Description

Processor Speed:Quad-core ARM Cortex-A53 @ 1.2 GHz

Operating System:RTOS-based

Memory:1 GB DDR3L RAM, 8 GB eMMC Flash

Ethernet Interface:Gigabit

I/O Capacity:16 Digital Inputs, 16 Digital Outputs

Safety Feature:Integrated Safety Control Module

Robot Arm Reach:1400 mm

Maximum Payload:7 kg

Operating Temperature Range:-20°C to +50°C

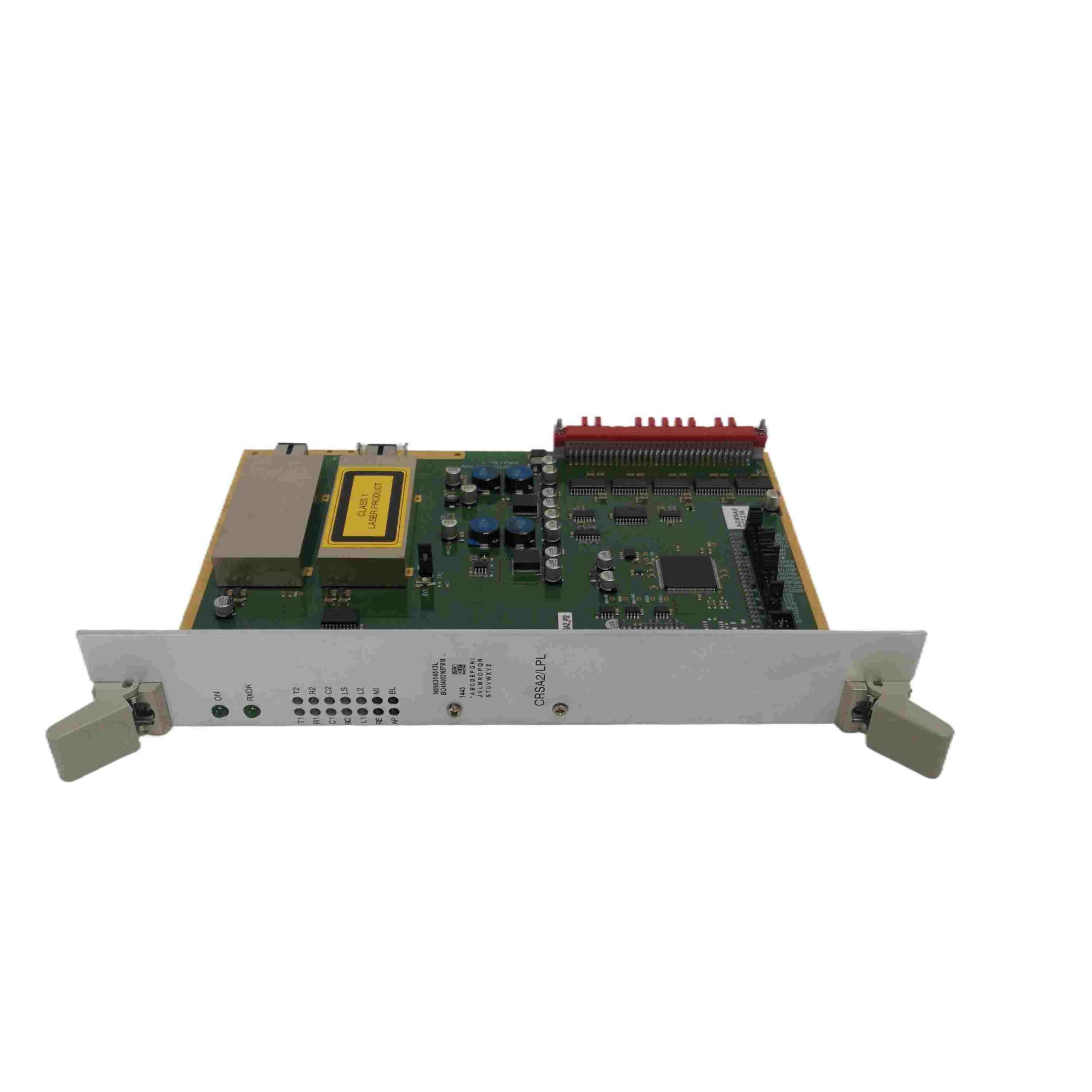

The ABB IRC5 Collaborative Robot Controller is designed for seamless integration into modern manufacturing environments, offering unparalleled control over complex robotic operations. With its robust ARM-based processor and efficient RTOS operating system, it ensures reliable performance under demanding conditions.

Featuring an extensive I/O capacity, the DSQC1015 board supports both digital inputs and outputs, facilitating direct control over a wide range of peripherals and actuators. This modular design enables easy configuration and scalability to meet diverse application needs.

The IRB 7600 Industrial Robot Arm, equipped with a high-performance motor and precision guidance systems, is capable of handling payloads up to 7 kg with exceptional accuracy and speed. Its extended reach of 1400 mm makes it suitable for a variety of tasks within manufacturing cells, from pick-and-place operations to more intricate assembly processes.

Safety is paramount in this automation suite, with an integrated safety control module ensuring compliance with industry standards. This feature allows for the creation of safe, collaborative workspaces where humans and robots can operate in close proximity without risk.

Operational flexibility is enhanced by the ability to adjust settings and perform maintenance remotely, thanks to its Ethernet interface and remote access capabilities. This not only reduces downtime but also optimizes operational efficiency across different stages of production.

Reviews

There are no reviews yet.