Description

1、 Product Overview

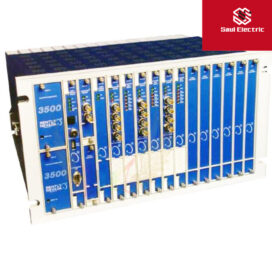

Model: 3300XL 8mm Vibration Probe

Specific model (possible): 330400-02-05 (specific model may vary due to product updates or customization)

Brand: Bently Nevada

2、 Technical features

Measurement range:

This probe belongs to the 3300 XL series and is widely used for measuring shaft vibration, shaft displacement, differential expansion, key phase, and rotational speed.

The linear range may vary depending on the specific model and configuration, but typically has high sensitivity and accuracy.

Electrical performance:

Power requirements: When there is no safety barrier, it is required to be between -17.5Vdc and -26Vdc, with a maximum current of 12mA.

The output voltage is proportional to the distance between the probe tip and the observed conductive surface, and can measure static (position) and dynamic (vibration) values.

Physical characteristics:

Probe diameter: 8mm, suitable for various measurement scenarios.

The working temperature range of the probe and extension cable is -52 ° C to+177 ° C (standard probe), and the high-temperature probe can withstand higher temperatures.

The probe cable adopts a patented CableLoc design, providing a secure connection and high tensile strength.

Anti interference capability:

The 3300 XL Proximitor sensor has strong resistance to radio frequency interference (RFI) and electromagnetic interference (EMI), meeting the requirements of European CE certification.

No special shielding conduit or metal casing is required, reducing installation costs and complexity.

3、 Application scenarios

Widely used in industries such as power plants, refineries, chemical plants, steel plants, water pump plants, fan plants, etc.

Used for online measurement and protection of vibration in large rotating machinery shafts such as steam turbines, water turbines, blowers, compressors, air compressors, gearboxes, water pumps, etc.

4、 Installation and maintenance

Installation steps:

Prepare necessary tools and materials, such as multimeters, small adjustable wrenches, open-end wrenches, etc.

Set the voltage value before installation to ensure that the shaft position is in the middle of the total string.

Use electrical or mechanical gap measurement installation method to determine the position of the probe, and screw the probe into the bracket in a clockwise direction.

During the installation process, be careful to avoid twisting the cable and ensure that the probe remains disconnected from the cable until it contacts the end face of the shaft before reconnecting.

Maintenance precautions:

Regularly check the installation status and working performance of the probe to ensure the accuracy of the measurement results.

During unit maintenance, pay attention to the disassembly sequence and force control of the probe to avoid damaging it.

Regularly inspect and maintain the preamplifier and cables to ensure the stability and reliability of signal transmission.

| 146031-01 |

| 125800-01 |

| 149992-01 |

| 125680-01 |

| 133323-01 |

| 3500/05-01-02-00-00-01 |

| 1900/65A-00-01-03-01-01 |

| 1900/65A-00-01-03-01-01 |

| 3500/65-01-00-R0 |

| 190501-09-00-00 |

| 330105-02-12-10-02-05 |

| 330171-00-12-10-02-05 |

Reviews

There are no reviews yet.