Description

Bently1900 series:

1900/17

1900/27

1900/65A

1900/65A-01-01-03-01-00

1900/65A-01-01-00-00-00

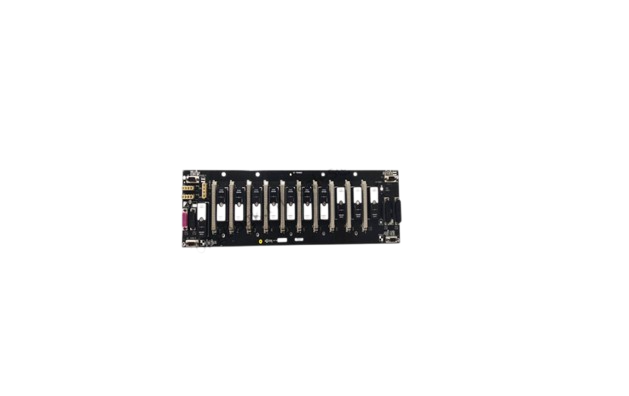

The following is a detailed analysis of the “1900/65A-01-01-00-00 Bently Monitor PLC Control System Module”:

1、 Module Overview

The 1900/65A-01-01-00-00 Bently monitor is a high-performance equipment monitor that is particularly suitable for continuous monitoring and protection in various industrial and mechanical applications. This monitor integrates the functions of a PLC (Programmable Logic Controller) control system, enabling real-time monitoring and precise control of equipment status.

2、 Module Features

Multiple inputs and outputs:

Provide multiple sensor inputs and temperature inputs, supporting various sensor types such as accelerometers, velocity sensors, or proximity sensors.

Equipped with six relay outputs and four 4-20mA recorder outputs, as well as a dedicated buffer output, to meet various control requirements.

Advanced configuration and communication:

Users can use the 1900 configuration software to flexibly configure the monitor, including setting sensor input types, output states, etc.

Supports Modbus communication protocol, allowing the monitor to exchange data with external systems such as DCS (Distributed Control System), SCADA (Supervisory Control and Data Acquisition System), PLC, etc.

Data storage and upload:

The ability to permanently store configuration information in non-volatile memory ensures data security and reliability.

Support uploading configuration information to PC for easy remote management and maintenance by users.

Display screen and keyboard:

Supports optional display screens/keyboards, allowing users to view channel information or make subtle configuration changes through the display screen.

The display screen can be installed up to 75 meters (250 feet) away from the monitoring module, providing flexible installation options.

3、 Module application

The module of the 1900/65A-01-01-00-00 Bently monitor PLC control system is widely used in various industrial and mechanical applications that require continuous monitoring and protection. For example, it can be used to monitor the vibration status of wind turbines, equipment operation status in the oil and gas industry, and so on. By monitoring equipment status in real-time and providing warning information, this module helps reduce equipment failure rates, improve production efficiency, and enhance safety.

4、 Precautions

Before use, please carefully read the product manual and installation guide to ensure proper installation and configuration of the monitor.

Regularly check the operating status of the monitor and sensor input data to ensure its accuracy and reliability.

If you encounter any problems or malfunctions, please contact the supplier or professional technicians for repair and replacement in a timely manner.

Reviews

There are no reviews yet.