Description

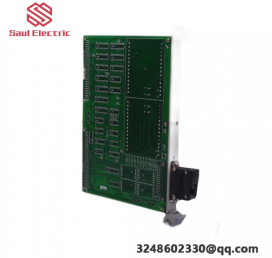

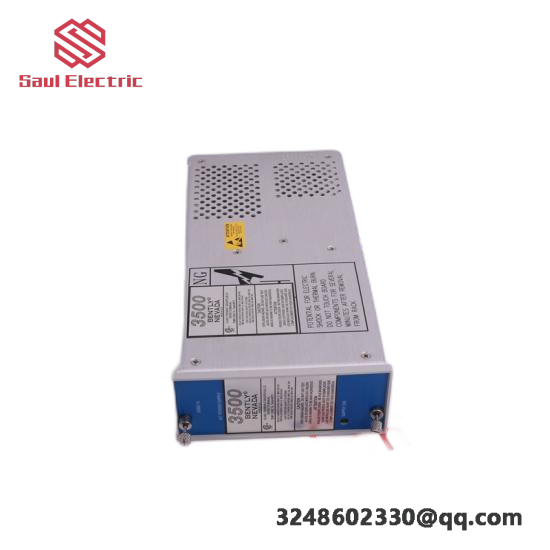

Brand:EPRO

Model:CON021/916-160

Product Type:Eddy Current Signal Converter

Supply Voltage Range:-23V to -32V

Weight:120 grams

Dimensions:100mm x 70mm x 40mm

Output Accuracy:±0.1%

Operating Temperature Range:-20°C to +85°C

Environmental Protection Rating:IP65

Communication Interface:RS485

The EPRO CON021/916-160 is an essential component for industrial automation systems, offering high accuracy and reliability in signal conversion. Designed with cutting-edge technology, this converter ensures seamless integration with existing control systems. Its compact size and lightweight design make it ideal for space-constrained environments. The device supports a wide range of supply voltages (-23V to -32V), ensuring compatibility with various industrial power sources. With a weight of only 120 grams, the EPRO CON021/916-160 is easy to install and maintain. The converter is housed in a robust enclosure with an IP65 rating, making it suitable for harsh industrial environments. The output accuracy of ±0.1% guarantees precise data transmission, enabling efficient process control and monitoring. The operating temperature range of -20°C to +85°C ensures reliable performance under extreme conditions. Furthermore, the EPRO CON021/916-160 features a standard RS485 communication interface, allowing for easy integration with other devices and systems. This versatile converter is perfect for use in manufacturing plants, power stations, and other industrial settings where precision and reliability are critical.

Reviews

There are no reviews yet.