Description

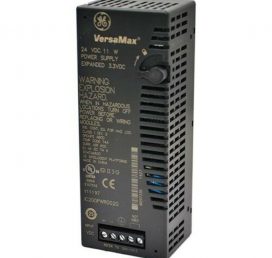

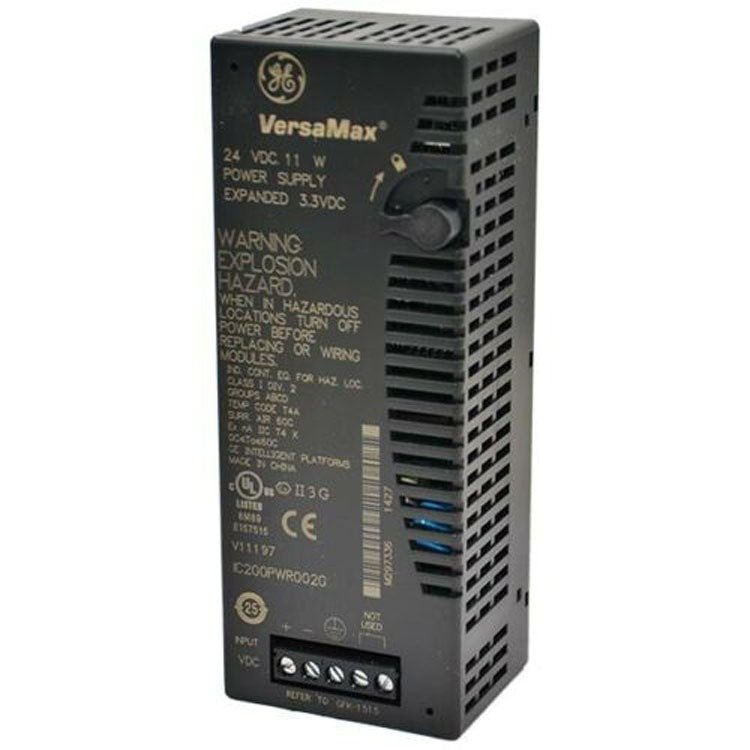

Operating Voltage:100V – 240V AC / 85V – 264V DC

Output Frequency:Up to 1 MHz

Processing Speed:16MHz Microprocessor

Floating Point Calculations:0.4 microseconds

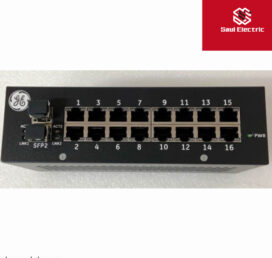

Communication Interface:RS-232, RS-485, Ethernet

Memory Capacity:128 KB RAM, 128 KB EEPROM

I/O Modules Compatibility:Wide range of input/output modules

Dimensions:2.4 x 4.9 x 1.3 inches

Weight:0.4 lbs

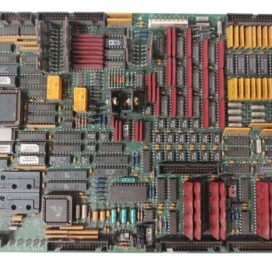

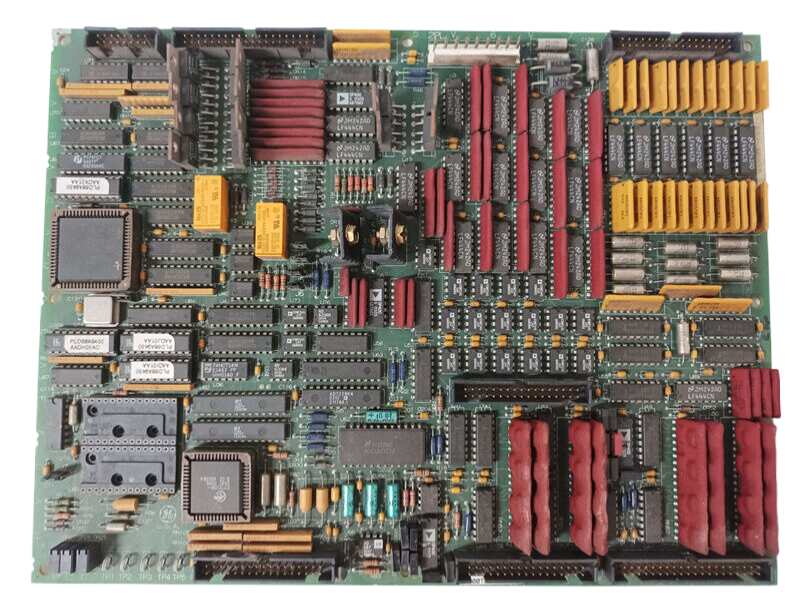

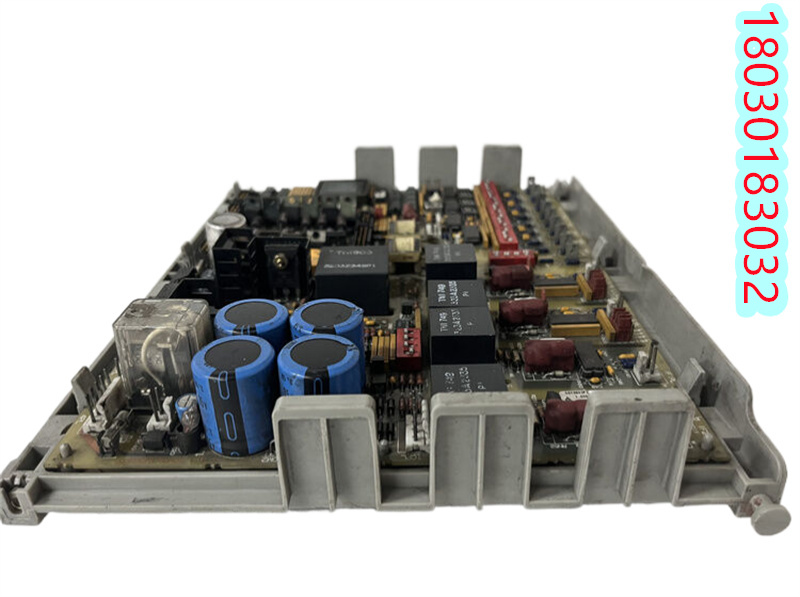

The General Electric IC697CPU782 is engineered for seamless integration into a single rack slot, making it an efficient choice for space-conscious industrial setups. Its robust design ensures reliability and longevity, backed by cutting-edge technology.

Featuring a powerful 16 MHz microprocessor, this controller is equipped to handle floating point calculations at incredible speeds, enhancing its capability to manage intricate industrial processes with precision.

With its rack-mounted backplane, the IC697CPU782 facilitates easy communication with a wide array of input/output (I/O) modules, enabling versatile connectivity and adaptability to diverse industrial applications.

For optimal operation, users can leverage the run/stop control switch or connect the device to a computer using the appropriate software, providing flexible control options to meet specific needs.

Equipped with high-end specifications, the General Electric IC697CPU782 is designed for industries seeking superior control solutions. Its comprehensive feature set, combined with its performance capabilities, makes it a valuable asset in enhancing productivity and efficiency on the factory floor.

Reviews

There are no reviews yet.