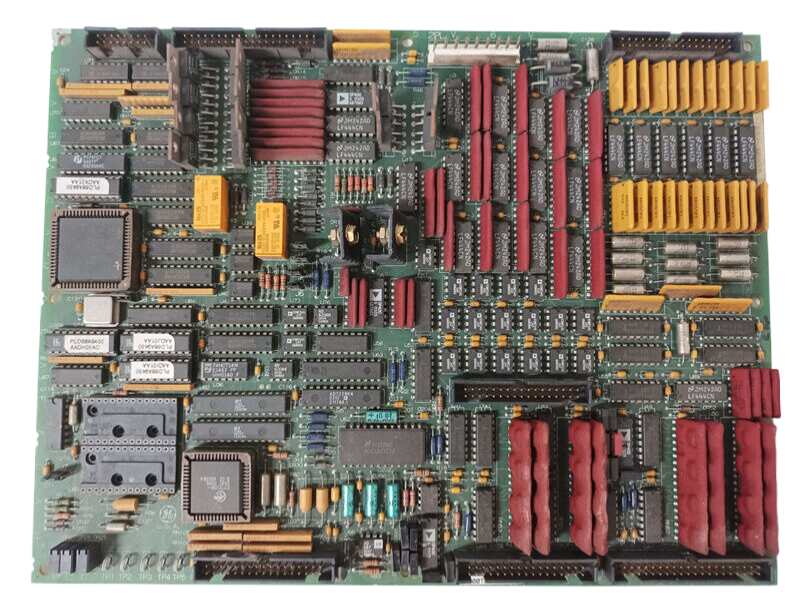

Description

Operating Voltage:24V DC

Display Size:5-inch Color LCD

Communication Interfaces:[“EtherCAT”,”RS-232″]

Operating Temperature Range:-10°C to +50°C

Memory Capacity:128 MB Flash, 16 MB RAM

Dimensions:225mm x 165mm x 70mm

Integrating cutting-edge technology, the FANUC A02B-0259-C221 Operator Panel is engineered to provide unparalleled user experience in industrial environments. Its high-resolution touchscreen ensures clear visualization and intuitive operation, facilitating quick adjustments and responses.

Equipped with robust communication interfaces, the panel seamlessly connects to various control systems, enabling real-time data exchange and monitoring. This feature is crucial for maintaining operational efficiency and productivity.

Built to withstand harsh industrial conditions, the operator panel boasts an extensive temperature range (-10°C to +50°C), ensuring reliability in diverse environments. Its compact design and lightweight construction make it easily deployable in tight spaces.

Featuring a powerful 800 MHz processor and ample memory (128 MB RAM, 128 MB ROM), the panel supports complex applications and software, enhancing its versatility in automation tasks. The inclusion of USB and Ethernet interfaces provides flexibility in integrating with existing systems.

Safety and security are paramount in industrial settings, which is why the FANUC A02B-0259-C221 Operator Panel incorporates industry-standard safety protocols. It ensures reliable performance and minimal downtime, contributing to the overall efficiency and safety of manufacturing processes.

Reviews

There are no reviews yet.