Description

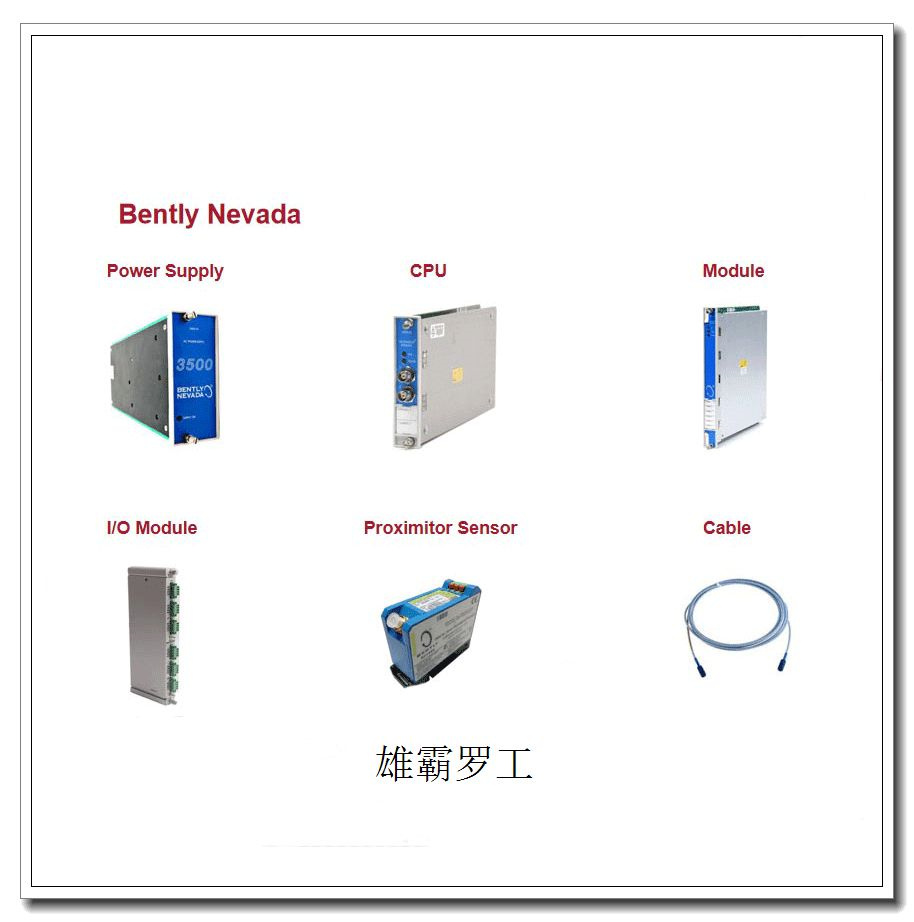

I will introduce the basic information, fault detection, precautions, and application scenarios of Bently Nevada’s 4/16 channel relays, communication gateways, monitors, sensors, power modules, display devices, interface workstations, Keyphasor modules, fault diagnosis connection panels, protective boxes, internal barriers, independent displays, and other products. Due to space limitations, this article will focus on introducing some products and provide general guidelines.

1. 4/16 channel relay

essential information:

4-channel relay: typically used in applications that require less relay output, such as small mechanical protection systems.

16 channel relay (such as 3500/33): Provides 16 relay outputs, suitable for large systems that require more output channels. These relay modules can be independently programmed to execute the required voting logic and include “alarm driver logic” for processing alarm inputs from the monitor.

Fault detection:

Check if the relay contacts are in good contact, without adhesion or open circuit.

Use testing equipment to verify whether the relay output meets expectations.

Check if the power and communication lines related to the relay module are functioning properly.

matters needing attention:

Ensure that the relay module is correctly installed and securely fixed to the rack.

Follow the manufacturer’s wiring and configuration guidelines.

Regularly check the working status of the relay module, promptly identify and address potential issues.

Application scenarios:

Widely used in mechanical protection systems in industries such as petroleum, chemical, and power, for monitoring and protecting critical equipment.

2. Communication gateway

essential information:

Communication gateway (such as 135145-01) is used to facilitate data exchange and communication between different systems or devices.

Fault detection:

Check if the power supply and communication interface of the gateway are functioning properly.

Use network testing tools to check network connections and data transmission.

View the logs and status information of the gateway to diagnose potential issues.

matters needing attention:

Ensure that the firmware and drivers of the gateway are the latest versions.

Follow the manufacturer’s cybersecurity guidelines to protect the gateway from network attacks.

Application scenarios:

In industrial automation systems, it is used to connect and integrate equipment from different manufacturers, enabling data sharing and remote monitoring.

3. Monitor, sensor, power module, etc

essential information:

Monitor: Used to monitor the operating status and parameters of equipment, such as vibration, temperature, pressure, etc.

Sensor: Convert physical quantities into measurable and processable electrical signals.

Power module: provides stable and reliable power supply for the system.

Fault detection:

For monitors and sensors, check whether their output signals are accurate, reliable, and consistent with expected values.

Check whether the output voltage and current of the power module meet the requirements, and whether there is no overload or short circuit phenomenon.

matters needing attention:

Regularly calibrate and maintain monitors and sensors to ensure their measurement accuracy and reliability.

Ensure that the working environment of the power module meets the manufacturer’s requirements and avoids adverse conditions such as overheating or humidity.

Application scenarios:

Monitors and sensors are widely used in the status monitoring and fault diagnosis of various industrial equipment.

The power module is an essential infrastructure in industrial automation systems, providing power support for various devices.

4. Display devices, interface workstations, etc

essential information:

Display device: used to display the operating status, parameters, and alarm information of the system.

Interface workstation: provides a human-computer interaction interface for configuring, monitoring, and maintaining the system.

Fault detection:

Check whether the screen of the display device is clear, without flickering or black screen phenomenon.

Check if the software of the interface workstation is running normally without crashing or lagging.

matters needing attention:

Ensure that the working environment of the display device and interface workstation meets the manufacturer’s requirements, avoiding direct sunlight or strong magnetic field interference.

Regularly backup the data and configuration information of the interface workstation to prevent data loss.

Application scenarios:

Display devices and interface workstations are important components of industrial automation systems, used to provide operators with intuitive system information and operating interfaces.

5. Keyphasor module, fault diagnosis connection panel, etc

essential information:

Keyphasor module: used to measure the speed and phase angle of rotating equipment.

Fault diagnosis connection panel: provides interfaces and connection points required for fault diagnosis.

Fault detection:

For the Keyphasor module, check if its measurement accuracy and stability meet the requirements.

When using the fault diagnosis connection panel for troubleshooting, ensure that the connection is correct and error free.

matters needing attention:

Follow the manufacturer’s operation and maintenance guidelines to ensure the correct use of the Keyphasor Module and Fault Diagnosis Connection Panel.

Application scenarios:

Keyphasor modules play an important role in the state monitoring and fault diagnosis of rotating equipment.

The fault diagnosis connection panel provides engineers with convenient troubleshooting methods, improving the efficiency and accuracy of fault diagnosis.

Main products, advantageous supply, sufficient inventory:

FOXOBORO I/A: AW51B, P0400YC FBM02, P0400YV FBM18, P0400ZE FBM04, P0914WM FBM241C,

FBM217 P0914TR, FBM242 P0916TA, CP40B P0961BC, FBM44 P0950BN, etc.

ALSOM MOTOROLA MVME Series: MVME 162-12 MVME 167-02、MVME177-004、 Waiting series.

HP: Workstations, servers, HP 9000 workstations, HP 75000 series spare parts, HP VXI testing equipment.

Honeywell: DCS system spare parts modules, HONEYWELL TDC series, QCS, S9000 and other spare parts.

Yaskawa: Servo controller, servo motor, servo drive.

Allen Bradley (Rockwell): 1756/1771/1785/2711 series, RelIance electromechanical products, etc.

Woodward: SPC valve position controller, PEAK150 digital controller.

Network Application: Data Storage Module.

SchneIder: MODICON 140 series, Quantum memory cards, Quantum power modules, etc.

XYCOM: XVME-103, XVME-690, VME bus and other spare parts.

FANUC: various spare parts such as modules, cards, drivers, etc. NOKI (Nikon): Card parts, module spare parts.

SIEMENS: SIemens IskamatIc, SIemens SImatIc S5,SIemens SImatIc C1, Numerical control system, etc.

Bosch Rexroth: Electronic transmission and control, I/O modules, PLC controllers, drives, etc.

Rexroth Indramat: Special product B&R: PLC

ABB: ABB MasterpIece200/AC450, ABB MastervIew 850/1, Advance OCS, MOD 30/MODCELL, MOD 300, BaIley INFI90,

ABB ProcontIc, ABB Procontrol. and other system spare parts.

Toshiba: DSV1-DA, VCM1X4 2N8C2184P001-G,VCMIX4,VPCPX1,VBMPX1, Wait.

HITACHI Hitachi: AIC200, CAM810, CPU800, CRT860, CTR850, CRT870, FLP800A, DHW850, etc.

Reviews

There are no reviews yet.