Description

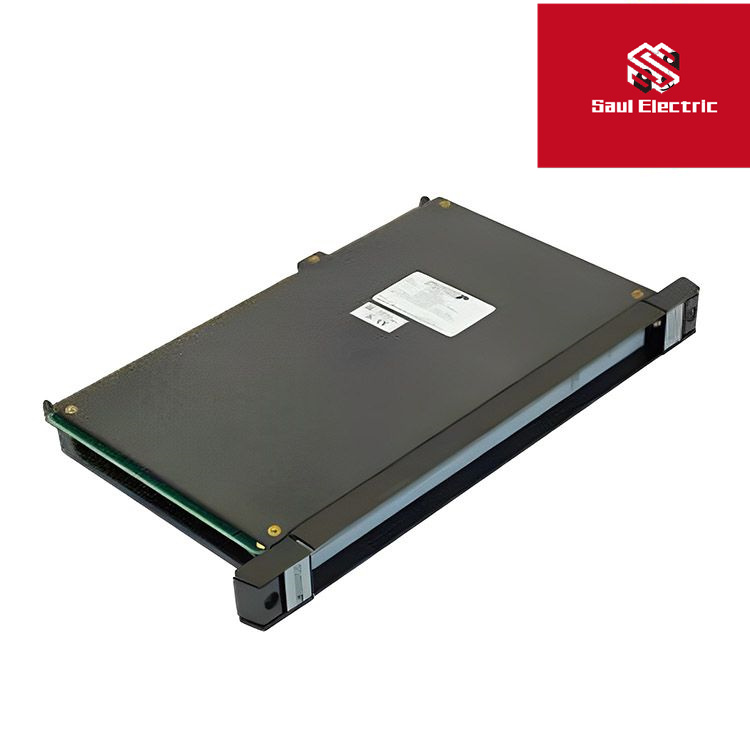

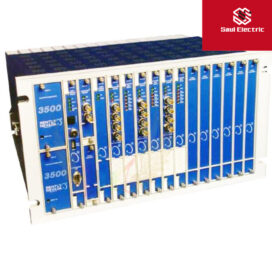

In terms of detecting and preventing false tripping and false tripping of rotating machinery, with over 80000 installations worldwide, the 3500 system provides automatic protection values through trip monitoring machines to prevent expensive damage when needed. It can also protect your machine and processes from false tripping, which may cause your operation to stop without reason, resulting in expensive shutdowns or production losses, When connected to System 1 * software, it also provides continuous status monitoring information for proactive maintenance plans.

The 3500 system combines a wide range of mechanical measurement parameter choices in the industry, as well as software configurations for almost all mechanical monitoring scenarios. The 3500 system fully meets the requirements of the American Petroleum Institute API670 standard for this type of system. It is a powerful and flexible system in the traditional Bentley Nevada framework system, with multiple features and advanced functions that other systems do not have.

Reviews

There are no reviews yet.