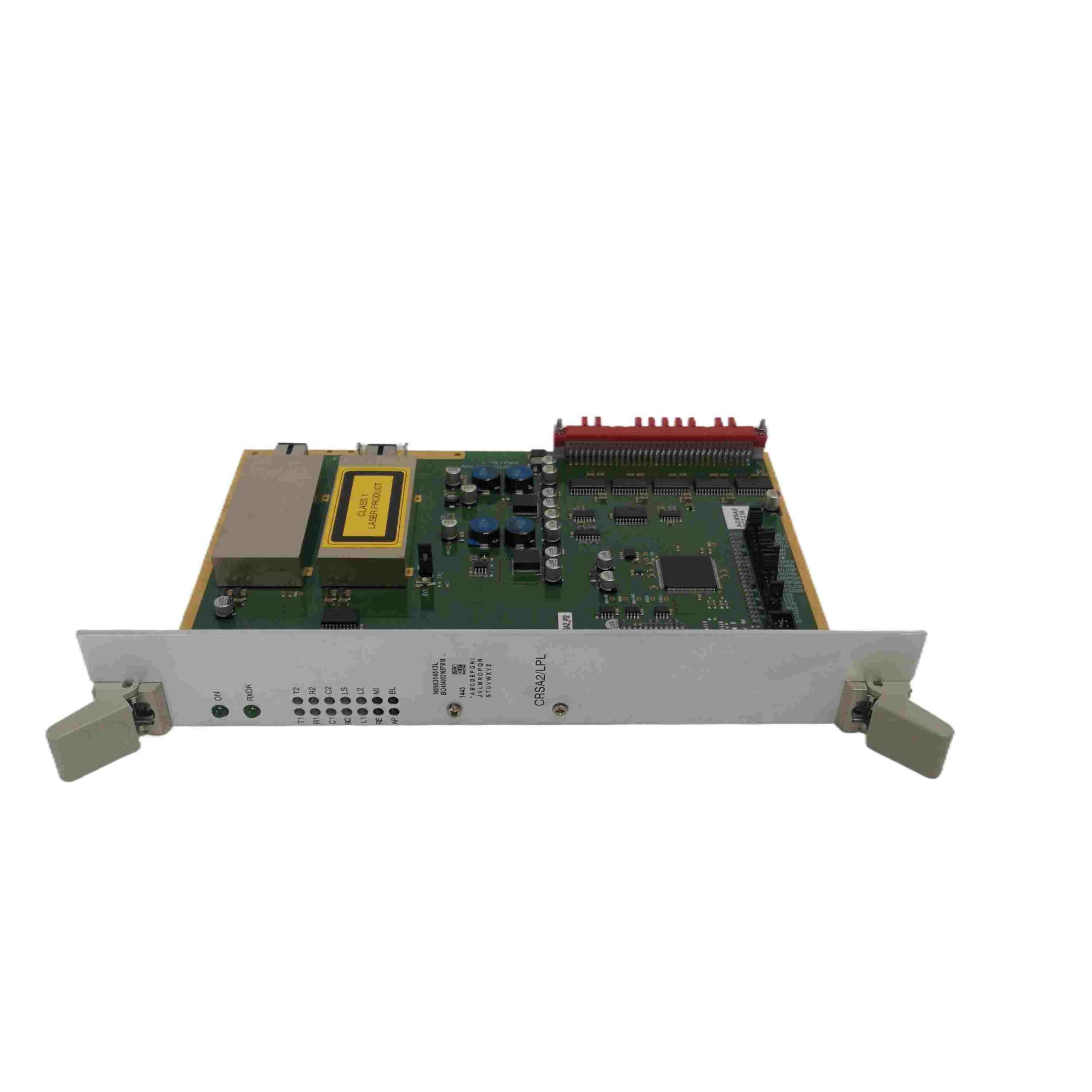

Description

Model:SPCIS22

Brand:ABB

Operating Voltage:24 VDC

Current Rating:50 mA

Number of Channels:8 Inputs / 8 Outputs

Communication Interface:Modbus RTU

Dimensions (WxHxD):74 x 90 x 112 mm

Weight:0.2 kg

The ABB SPCIS22 Control I/O Module is a cornerstone of advanced industrial automation, engineered for critical applications requiring precision and reliability. Its compact size and robust aluminum alloy construction ensure durability and longevity in demanding environments.

With an operating voltage of DC 24V and a current consumption less than 50mA, the module efficiently manages power usage, reducing overall system energy consumption. It supports MODBUS RTU communication protocol, facilitating seamless integration with existing control systems.

Equipped with 8 digital inputs and 8 digital outputs, this module offers versatile connectivity options for sensors and actuators, enabling precise control over industrial processes. Its IP20 enclosure type provides basic protection against dust and light splashes, suitable for most industrial settings.

The ABB SPCIS22 Control I/O Module is designed with ease-of-use in mind. It features intuitive configuration options and comprehensive diagnostics tools, allowing operators to quickly identify and resolve issues without extensive technical expertise.

For users seeking to enhance productivity and efficiency in their manufacturing or process control environments, the ABB SPCIS22 Control I/O Module is an indispensable tool. Its compatibility with various industrial standards ensures compatibility with a wide range of automation systems, making it a flexible addition to any industrial setup.

Reviews

There are no reviews yet.